What is (HTV) Heat Transfer Vinyl Sticker?

A Modern Technique that brings Elegance and Beauty to Any One Color.

Did you know that in today’s era, where brands strive to establish an emotional connection with their audience, they adopt simple, beautiful, and durable methods?

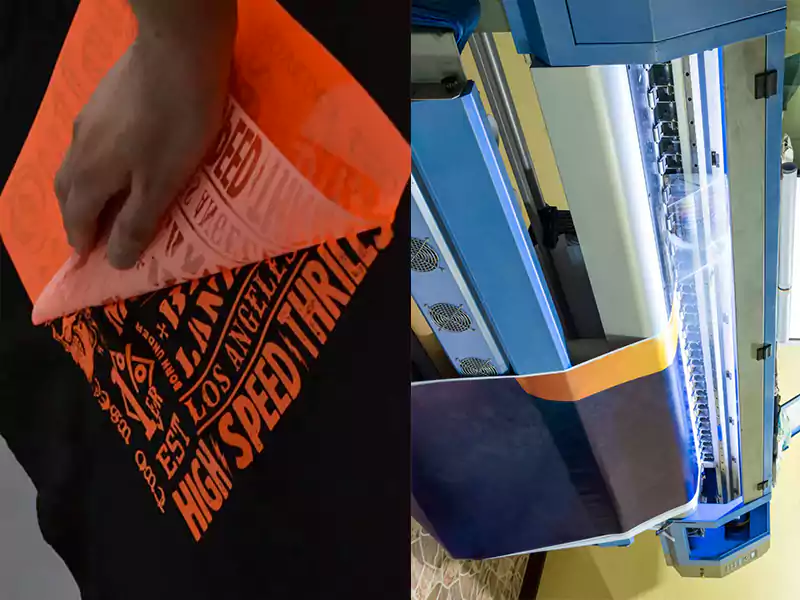

Heat Transfer Vinyl Sticker- Yes, a modern technology that not only enhances the beauty of your clothing but also brings your designs to life in a truly expressive way!

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Vinyl sticker Printed Products Collection.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Vinyl-sticker technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Vinyl-stickers adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

Heat Transfer Vinyl Sticker (HTV) is a special type of thin yet durable vinyl sheet that is applied directly to fabric using heat and pressure. Its biggest advantage is that it comes in specific colors, textures, and qualities, allowing you to give every type of garment, such as t-shirts, hoodies, jackets, tracksuits, or caps a completely new, branded, and attractive appearance. The use of Heat Transfer Vinyl Sticker has become a crucial pillar of quality, innovation, and creative expression in today’s garment industry. Whether you are a small clothing brand or a manufacturer working at the international level, HTV provides the elegance and durability that allow every outfit to tell its own story. The art of enhancing the beauty of fabric or any surface has always fascinated the world, and vinyl printing is a modern, charming, and lasting style of that art. When it comes to a technique that offers design precision, vibrant colors, and full confidence in quality, vinyl printing stands at the forefront. Vinyl printing is a process in which designs are cut on special vinyl sheets and then transferred onto fabrics or other items through heat. This technique not only adds detail and finesse to the designs but also breathes new life into every color and every line. Whether you want to build your brand identity, enhance a team uniform, or give your products a unique identity, vinyl printing is an exceptional choice. In today’s fast-paced world, where every brand seeks it own identity, vinyl printing offers the perfect solution for those who want high-quality, eye-catching results in less time. This technique is especially ideal for businesses aiming to leave a lasting impression on their products and win customer loyalty. The biggest beauty of vinyl printing lies in its durability and longevity, while making even the smallest artwork stand out like a masterpiece on canvas. That is why vinyl printing is rapidly gaining popularity not only on clothing, but also on bags, caps, t-shirts, hoodies, tracksuits, jackets, and countless other products. If you want quality, innovation, and beauty at the same time, vinyl Sticker should be your first and last choice!

History of Heat Transfer Vinyl Sticker. From a Simple Sheet to Stunning Creatures

The foundation of vinyl printing was laid in the 1930s, when a synthetic material called polyvinyl chloride (PVC) was first invented. In 1930, Waldo Simon, an American chemist, developed a method to make polyvinyl chloride more flexible and usable. This discovery gave birth to the world of vinyl sheets and vinyl stickers. Initially, these sheets were used for advertising boards, vehicle signage, and wall decorations. Their standout feature was their resistance to water, dust, and harsh weather conditions, which made them an ideal choice for outdoor advertising. However, as printing technologies advanced over time, experts began to explore other creative uses for vinyl sheets. This led to the emergence of vinyl printing in the garment industry in the 1970s. Sports teams needed an available and visually appealing way to print players’ vinyl stickers onto fabric using special machines, a method we now know as Heat Transfer Vinyl Printing (HTV Printing).

Trust Us for the Success of Your Brand! Why are we the best choice?

When it comes to high-quality heat transfer vinyl sheets and outstanding vinyl printing, our company is your most reliable choice. We have a team of skilled craftsmen with extensive experience, who bring each design to life on fabric with precision and elegance. We use state-of the-art machinery and the latest technology to ensure every print is unmatched in beauty, durability, and refinement. For years, we have been working with clothing brands around the world, delivering quality, punctuality, and exceptional results. Whether your brand is small or large we are fully ready to turn your vision into reality!

Contact us today and give your brand the recognition it truly deserves!

Key Features of (HTV) Heat Transfer Vinyl Sticker.

Vinyl printing on fabric quickly gained popularity due to its outstanding features:

• Highly durable

• Resistant to harsh weather conditions

• Ideal for simple, elegant, and professional designs

• Colors remain vibrant even after washing

• Cost-effective solution for creating personalized designs

• Fast turnaround on small orders.

• Adheres strongly to the fabric and does not peel off when washed

• Provides a smooth and clean finish

• Can be used on various types of surfaces

• Lightweight and comfortable to wear

• Offer long-lasting performance and professional-grade quality

• Available in a specific (single) color

Fun Fact. Did you know?

The popularity of heat transfer vinyl soared in the 1990s when small brands began using it as a low-cost way to enhance their designs. Today, HTV technology has become a priceless tool in the fashion industry! Modern thermal transfer vinyl sheets are no longer limited to basic solid colors- they are now available in metallic, glitter, fluorescent, and even 3D effect finishes. This allows every brand to express its identity in a more unique and impactful way!

Types of Heat Transfer Vinyl (HTV) sheets:

Heat transfer Vinyl sheets are highly popular in today’s fashion and apparel industry. To cater to different design needs and creative styles, various types of HTV sheets are available in the market:

1. Standard (Regular) Heat Transfer Vinyl:

This is the most common and basic type, available in a range of solid colors (like white, black, red, blue, etc). it easily transfers onto fabric and is considered ideal for everyday use.

2. Metallic Heat Transfer Vinyl:

These sheets give the look and shine of metals like gold, silver, bronze, and more. Metallic vinyl sheets are especially used for promotional clothing, fashion wear, and premium products.

3. Fluorescent (Neon) Heat Transfer Vinyl:

Available in very bright and bold colors, these sheets stand out prominently during the day or night. They are popular for youth clothing, sportswear, and promotional events.

4. Glitter Heat Transfer Vinyl:

Infused with sparkling particles, these sheets add a special and attractive look to any garment. Commonly used for party wear, women’s fashion, and kids’ apparel.

5. 3D (Puff) Heat Transfer Vinyl:

This unique type of sheet slightly expands when heat is applied, creating a 3D raised effect on the fabric. These sheets are highly popular among fashion designers seeking a distinctive and bold style.

Why Choose Heat Transfer Vinyl Sticker?

Because it:

• Offers a fast production solution

• Enables branding at a low cost

• Saves you from complex or expensive printing methods

• Delivers professional results even in small quantities

How to Care for Garments with Vinyl Printing – Instructions & Care

Clothes designed using Heat Transfer Vinyl are a mark of beauty and quality, but to preserve their longevity and freshness, some precautions are essential. By following these guidelines, you can keep your vinyl-designed garments looking new and attractive:

Precautions Before Washing:

• Always turn the garments inside out before washing, so the design is not directly exposed to friction or pressure.

• Wait at least 24 hours after the first wear before washing, to allow the vinyl to fully bond with the fabric.

• Use cold or lukewarm water; very hot water may weaken the vinyl adhesives.

Proper Washing Method:

• Hand washing is the best option, but if using a washing machine, choose the gentle cycle.

• Avoid harsh detergents or bleach, as they can dull the print’s color and shine.

• Use mild and color-safe detergent to preserve both the fabric and the print.

Precautions While Drying:

• Do not dry vinyl-printed garments in direct sunlight. Instead, let them air dry naturally in the shade.

• Avoid using a tumble dryer, as excessive heat can melt or wrinkle the vinyl.

Precautions While Ironing:

• Iron the garment inside out to protect the vinyl design from direct heat.

• Iron the garment inside out to protect the vinyl design from direct heat.

• If ironing directly on the vinyl is necessary, place a thin cloth or ironing sheet over the

vinyl and iron gently.

• Avoid using excessively hot irons.

Special Instructions

• Avoid repeatedly pulling, twisting, or applying unnecessary pressure on the vinyl design.

• Do not use chemical cleaning agents or dish washing solutions.

• Avoid repeatedly pulling, twisting, or applying unnecessary pressure on the vinyl design.

• Do not use chemical cleaning agents or harsh washing solutions.

• When folding clothes, avoid putting pressure on the vinyl area so the design retains its original shape.

The Complete Procedure of Heat Transfer Vinyl Sticker

Remember!

Good care not only preserves the color, shine, and adhesion of the vinyl but also keeps your clothes looking beautiful and new for longer.

The Complete Procedure of Heat Transfer Vinyl Printing:

1. Design Preparation:

First, the desired design or logo is created on a computer using graphic design software (such as Adobe Illustrator or CorelDRAW). This design must be absolutely accurate, clean, and suitable for cutting so that it can be transferred onto the vinyl sheet in the best possible way.

2. Setting up for Cutting the Design:

Once the design is complete, it is uploaded to a cutting machine (such as Cricut or Graphtec Cutter). Here, it is determined where and at what depth the vinyl sheet will be cut so that only the desired design is cut and the backing sheet remains intact.

3. Cutting the Vinyl Sheet:

The cutting machine cuts the design onto the vinyl sheet with specific pressure and blade settings. This process requires extreme care so that even the fine details of the design remain perfectly intact.

4. Weeding (Removing Unnecessary Vinyl):

After cutting, the extra vinyl is removed by hand or with the help of weeding tools, so that only the original design remains. This stage requires patience and skill.

5. Transferring the Design onto Transfer Tape:

To easily adhere the design to the fabric, it is transferred onto transfer tape, which helps to keep the design in its correct position.

6. Preparing the Fabric:

The fabric on which printing is to be done is first thoroughly cleaned and pressed to make it smooth so that no wrinkles or moisture affect the design.

7. Placing the Design on the Fabric:

With the help of transfer tape, the design is placed on the fabric at the correct location. This stage is very important so that the design is not crooked or placed in the wrong spot.

8. Using the Heat Press Machine:

Now, the heat press machine is set to a specific temperature (usually between 150°C and 170°C), pressure, and time (approximately 10-15 seconds), and pressure is applied to the design. The correct combination of temperature, time, and pressure is crucial for the durability and beauty of the vinyl.

9. Removing the Transfer Tape:

After the heat press, the fabric is allowed to cool for a short while, and then the transfer tape is gently removed. Now, the design is beautifully adhered to the fabric.

10. Final Quality Check:

Finally, the completed product is inspected to ensure that no part is incomplete or damaged, and that the design is completely clean, shiny, and well-attached to the fabric.

Vinyl Printing: Basic Principles, Evolution, and Importance in the Modern Era

The basic principle of vinyl printing remains the same as its origin: a high-quality vinyl sheet of a specific color is taken, cut according to the design, and then transferred onto fabric or other products without any direct multi-color printing. products without any direct multi-color printing. This simple yet effective technique originated as an industrial innovation in the 20th century, and over time, it has transformed into a creative art, becoming a symbol of quality, sophistication, and lasting results. In today’s modern era, vinyl

printing has established its own distinct and prominent identity in the fashion industry and personalized garments. Whether it’s a small logo or a large text, every design can be transferred onto clothes in a highly professional and attractive manner with the help of vinyl printing. This technique not only provides standard results but also gives brands and fashion designers the opportunity to fully express their creative potential.

FAQ'S

What is Heat Transfer Vinyl (HTV) Printing?

Heat transfer vinyl printing is a special method in which a colored vinyl sheet is cut to create a design, and then transferred onto fabric or another material using heat and pressure. Unlike direct printing, the design is applied through a sheet, resulting in a durable, beautiful, and high-quality finish.

Which fabric is best for Vinyl Sticker?

The best results are achieved on 100% cotton, 100% polyester, or cotton-polyester blend fabrics. Vinyl adheres best to these fabrics and provides long-lasting results.

For what types of orders is Vinyl printing more beneficial?

Heat transfer vinyl printing is the best and most cost-effective solution for small orders, personalized garments, branded uniforms, promotional items, and limited edition designs.

What is the difference between Heat Transfer Vinyl and Screen Printing?

Heat transfer vinyl uses a vinyl sheet, while screen printing involves printing ink directly onto the fabric. Vinyl printing is more intricate, flexible, and ideal for small orders, whereas screen the fabric. vinyl printing is more intricate, flexible, and ideal for small orders, whereas screen printing is better suited for large quantities of identical designs.

Which Vinyl Sticker is suitable for all types of designs?

Small to large designs, logos, text, or patterns can all be beautifully transferred using vinyl printing. However, for very intricate or multi-colored gradient designs, other printing methods mayn be more suitable.

How many colors can be used in one design?

In vinyl printing, a separate sheet is used for each color. Generally, 2 to 3 colors can be easily managed, but other printing methods are better for very colorful or shaded designs.

Does Vinyl Printing last long on fabric?

Yes, if good quality vinyl is used and care instructions are followed, vinyl printing can last for many years without peeling or cracking.

Can Vinyl-printed clothes be ironed?

Yes, but always iron the garment inside out and do not iron directly over the vinyl. It is best to place a cloth or paper over the vinyl and iron on a low heat setting.

Is Vinyl printing eco-friendly?

Many vinyl sheets are now made from eco-friendly materials, but generally, vinyl printing is not

completely biodegradable. However, modern companies are using less toxic and recyclable vinyl.

What is the correct way to wash clothes with vinyl prints?

Clothes with vinyl prints should always be washed inside out in cold water with a gentle hand. Harsh chemicals or bleach should be avoided, and the clothes should not be rubbed or wrung out excessively.

Is Vinyl Sticker waterproof?

Vinyl itself is waterproof, but complete waterproofing depends on the fabric and the overall

technique. Under normal circumstances, vinyl-printed clothes are water-resistant.

More Questions? Contact Us!

If you still have any questions or would like personalized advice for your product, please do not

hesitate to contact us. Our expert team is available 24 hours a day to address all your concerns and help you create the brand of your dreams. Whether it’s choosing a design, material guidance, or the complete order process, we are with you every step of the way!

Can vinyl-printed clothes be put in the dryer?

It is best to air dry vinyl-printed clothes. If you must use a dryer, choose a low heat or delicate mode to prevent damage to the vinyl.

Can a damaged vinyl print be repaired?

If a vinyl print is slightly peeling or lifting at the corners, it can be repaired with gentle heat and re-pressure. However, in case of complete damage, it is better to apply new vinyl.

Contact us

Choose us to take your brand to new heights!

We are not only limited to working with heat transfer vinyl sheets; rather, our company is a complete clothing manufacturing house with the potential reality through over 15 advanced printing techniques such as screen printing, sublimation printing, DTF printing, embroidery, rhinestones, and other unique methods. We are not only unparalleled in quality but also provide comprehensive services, including free sampling, free mock-ups, professional tech pack development, and 24/7 customer support to provide you with complete guidance at every stage. Our expert team works with modern machinery, world-class production processes, and a creative vision to ensure that every product reflects beauty, durability, and confidence. We provide door to-door delivery service worldwide, and through our worldwide shipping, no matter where your brand is in the world, quality products are delivered to you on time and safely. Thousands of clothing brands have trusted us — now it’s your turn to contact us to take your brand to new heights!

If you are launching a new clothing brand or want to add innovation and uniqueness to your existing brand, our company is the realization of your dreams. We not only provide high-quality heat transfer vinyl sheets and advanced vinyl printing services but also offer you a complete solution – whether it’s about providing high-quality heat transfer vinyl sheets, excellent printing through modern machines, or transferring your designs onto clothes in a completely professional manner. We have creative experts, state-of-the-art machinery, and years of experience that turn every project of yours into a success. We provide all-over printing services on custom t-shirts. hoodies, jackets, tracksuits, and many other products. Our company understands the needs of every brand and provides quality, unique, and long-lasting solutions accordingly. Give us the opportunity today to turn your dreams into reality – because your brand deserves the best! Contact us today and make your brand unparalleled – and take the first step in turning your dream brand into reality!