What is Screen Printing?

In the world of apparel, if there is one printing technique that symbolizes maximum durability,

beauty, and premium results, it is screen printing. This technique transfers designs vividly onto fabric and captivates customers with its lasting appeal and elegance. Screen printing involves using a special mesh or screen through which ink is transferred onto the fabric. This method is particularly ideal for single-color garments, bulk orders, and branded shirts.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

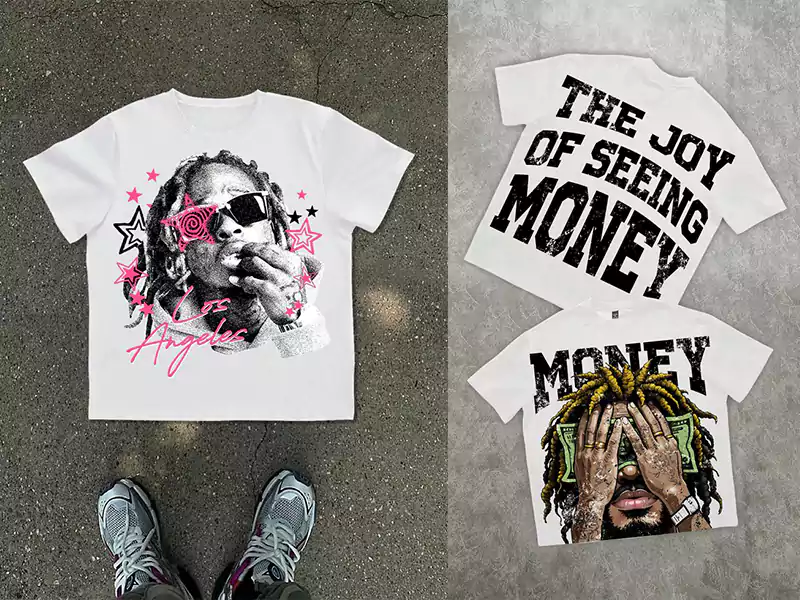

From Concept to Perfection Explore Our Screen Printed Products Collection.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Screen printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Screen printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

Why Are We the Best Choice?

We are not just any Screen Printing service provider- we are a complete clothing manufacturing company, managing everything from fabric production to printing, stitching, packing, and shipping under one roof. Your brand is unique, so should be your printing. We understand that every design, every color, and every thread is connected to a customer’s dream. That’s why we treat every project as a reflection of the brand’s identity. Whether you are launching a new brand or revamping an existing business, we are here to support you at every step.

The History of Screen Printing

A Moment of Creation Where Art Breathed Life into Fabric:

“An ancient art that, even after thousands of years, continues to speak in colors to the modern world.” The art we know today as screen printing has its roots deep in ancient civilizations. It began in the 3rd century BC in China, where silk meshes were stretched on wooden frames, and dyes were transferred through specially crafted stencils. Later, the technique reached Japan, where it was refined further, with intricate and delicate patterns brought to life on fabrics. For a long time, this method remained confined to the East until the 18th century, when Europe got its first taste of it. Initially, its use in the West was limited due to the high cost and rarity of delicate silk meshes. However, with the invention of synthetic threads like Nylon, the technique gradually evolved into an industry. By the 20th century, screen printing had become a commercial revolution. Especially in the 1960s, when pop art pioneer Andy Warhol created his famous screen print of Marilyn Monroe, it sent waves through the worlds of fashion and art. That was the moment screen printing transformed from just an art form into a powerful medium of expression. This history tells us that screen printing is not just a technique, it is a story spanning centuries, a story that has given fabric its identity in every era.

Two main Methods of Screen Printing:

• Manual Screen Printing:

This method is done by hand, where a person manually controls the screen, ink, and pressure. It is ideal for small businesses, unique, or limited edition prints.

• Automatic Screen Printing:

This method uses advanced machines that print automatically. It is best for speed, uniformity, and high-volume printing. Just place the fabric, and the machine does the rest.

The Core Element of Screening Printing: The Mesh ( Screen Mesh)

“It’s not just a mesh- it’s your brand’s first impression.”

• The Screen is made from a special type of mesh, usually polyester.

• A designed stencil is created on it, allowing ink to pass through specific areas.

• The mesh count ( e.g, 110, 156, 230 mesh) determines how fine or thick the print will be.

Types of Inks and Effects Used in Screen Printing:

Screen Printing is not just about applying colors- behind every print is the power of specific inks and effects. These inks not only enhance the durability, appearance, and finish of the design but also contribute unique textures, shine, softness, and functionality, making each print stand out. Whether it’s a flat and simple print or a glossy, filled effect, the choice of inks and effects gives every design a distinct identity. That’s why we carefully select inks for every printing project to ensure your brand not only looks stunning but also leaves a lasting impression.

Top Picks:

• For durability and shine. Plastisol ink is the best.

• For softness and a natural look. Water-based ink is the ideal choice.

1. Plastisol Printing:

Plastisol printing is the most well-known and popular form of screen printing, which creates a thick, glossy, and durable layer on the surface of the fabric. This ink not only appears vibrant in deep colors but also retains its shine and structure even after multiple washes. At Ascension International, we recommend Plastisol printing when brands need bold designs and long-lasting quality. This ink delivers the best results on cotton and blended fabrics. If you want your logo or artwork to remain clear and attractive for years. Plastisol printing is the ideal choice. It is especially favored in streetwear and promotional t-shirts.

2. Water-Based Printing:

Water-based ink is a natural, soft, and eco-friendly solution that absorbs into the fabric, making it look as if the design is part of the fabric itself. It is especially suitable for light colored fabrics, where softness and breathability are key. At Ascension International, we use this ink for brands that value sustainability, simplicity, and a natural feel. Water-based prints not only feel soft on the skin but also maintain their quality after washing. This printing is highly popular in children’s wear, women’s clothing, and summer garments.

3. Discharge Printing;

Discharge printing is an advanced technique that allows bright and light colored prints or dark fabrics. This ink works by chemically removing the original dye of the fabric and replacing it with a new dye color, making the print feel like an actual part of the fabric. Ascension International uses this technique for soft-finish and breathable designs. The result is an extremely soft, breathable, and long-lasting print. It is most effective on 100% cotton fabrics, especially when creating elite designs on dark garments.

4. Puff Printing:

In puff printing, the ink expands when heated through a special chemical process, creating a 3D effect. The print becomes tactile and visually striking, making it stand out both to the eye and the touch. Ascension International offers this printing to brands seeking a blend of innovation, style and artistry. Puff printing is especially charming for kids’ clothing, fashion shirts, and branded sweatshirts. If you want your print to feel as special as it looks, puff printing is the way to go.

5. Flock Printing:

Flock printing is a unique technique in which fine fiber material is adhered to a glue-based ink, giving the design a velvety, soft, and textured feel. This results in a rich and luxurious look. At Ascension International, we use this technique for customers who want to give their garments a premium feel. Flock printing is especially effective for logos, text, or small designs, making it an ideal choice for fashion brands, boutique styles, and high-end artwork.

6. Crack Printing:

Crack printing intentionally creates fine cracks in the design, giving it a vintage, aged, or handcrafted look. It is often used for fashion shirts, band merchandise, or retro-looking artwork. Its greatest strength is that each print forms a unique pattern, making every piece one-of-a-kind.

7. Foil Printing:

Foil printing provides a shiny, metallic finish, applied to the fabric using gold, silver, or holographic sheets. This printing style offers a glamorous, luxurious, and eye-catching effect. Ascension International recommends foil printing for special occasions, party wear, or premium brands. If you want your design to stand out and truly make a statement, foil printing is the perfect option.

8. Glitter Printing:

Glitter printing uses ink embedded with sparkling particles that shimmer when light hits them. This style is ideal for fashion wear, kids’ apparel, or party garments. At Ascension International, we use a fine, adhesive-grade glitter to ensure the sparkle lasts longer. This ink makes your design glamorous, vibrant, and memorable.

9. Glow in the Dark Printing:

This special ink absorbs light and glows in the dark, making garments fun and unique for kids, night events, or festivals. At Ascension International, we create glow-in-the-dark prints for special clients who want to combine innovation with fun. The print appears normal during the day, but glows at night, creating a surprising and playful effect.

10. UV Printing:

In UV printing, the ink used reacts to sunlight or UV rays, causing the design to appear faint or invisible under normal light, but becomes vibrant and colorful in sunlight. Ascension International introduces this innovative technique for brands that want to attract customers with a secretive and surprising effect. This printing is especially popular among youth and creative designs.

11. Silicone-Based Printing:

Silicone printing is a flexible, soft, and rubber-like technique primarily used in sportswear, activewear, and high-frequency washable garments. Ascension International prefers silicone inks for clients who need highly durable and fabric-friendly prints. Its soft touch and strong hold consistently deliver premium quality results.

“Think, Sketch, Screen, and Print”-How Screen Printing Is Done

“Every Color, Every Line, Every Layer”

• Design Preparation:

This is the first most essential stage. Design is usually created in vector software like Adobe Illustrator, CorelDRAW, or other. At this stage, the size, detail, edges, and colors of the design are arranged with great precision. Afterwards, a separate film is prepared for each color, printed in black and white, which is used to create the stencil on the screen.

• Screen and Stencil Preparation:

Once the film is ready, it is placed on a screen mesh coated with a light-sensitive emulsion chemical. The chemical hardens everywhere except where the design is, which remains soft. Later, the soft part is washed off with water, and the design transfers onto the screen as a stencil.

• Ink Application (Stage Printing):

Now, the screen is placed on the desired fabric or garment. A separate screen is used for each color. Ink is poured onto the screen and spread across the fabric with a squeegee using specific pressure, ensuring the design transfers accurately. This process can be done manually or using automatic machinery, depending on the order volume, design complexity, and budget.

• Drying (Process Curing):

After printing, the fabric is immediately passed under dryer heat, or a dryer belt conveyor so the ink dries completely and sets into the fabric. If the ink does not dry fully, it may get damaged during washing or wearing, which is why this step is critical.

• Quality Check and Final Touch:

Every printed garment is carefully inspected:

• Is the design sharp and clear?

• Did the ink bleed?

• Are the edges clean?

If any print is faulty, it is separated to ensure only top-quality products reach the customer. If needed, a light heat press is used for final finishing, making the fabric look cleaner and more professional.

Benefits and Challenges of Screen Printing:

“Where quality, durability, and visual appeal matter-screen printing stands out, despite few hurdles.”

1. Long-lasting and Durable Paints:

A key strength of screen printing is its durability and resilience. Once a design is printed, it retains its color and quality for years. Even after repeated washing or daily wear.

2. Rich and Deep Colors:

The ink used in this method penetrates deep into the fabric, resulting in colors that are more vibrant, shiny, and long-lasting.

3. Low Cost at High Volumes:

If you need to print hundreds or thousands of units, screen printing becomes very cost-effective, as once a screen is made, the cost per unit drops significantly.

4. Suitable for All Fabric Types:

Whether it’s cotton, polyester, or fleece-screen printing delivers excellent results on all types of fabrics, especially on high GSM garments.

5. Flexible Design Options:

Screen printing allows for the printing of graphics, logos, or text in various sizes, and custom colors can be matched exactly as per the client’s specifications.

Challenges/Drawbacks of Screen Printing:

• Expensive for Small Quantities:

If you only need to print on 10 or 20 shirts, the cost per unit becomes high, as a separate screen is required for each color, making it less economical.

• Limited Color Range:

If your design has too many colors or gradient effects, screen printing may struggle to deliver those results. For such designs, digital printing, DTF (Direct to Film), or sublimation might be more suitable.

• Lack of Details in Complex Images:

Photographic or highly detailed designs may not appear clearly with screen printing unless a very high mesh count is used.

• Time-Consuming Setup:

Creating screens, preparing inks, and setting up the process is time-intensive, which can cause delays in urgent orders.

FAQ'S

Screen Print Removal Solutions?

There are several ways to remove screen prints, depending on the fabric type and the ink used. A common method is to soak the printed area in warm water to loosen the ink layer. Then, gently scrubbing with a soft brush or cloth helps lift the print off. If the print does not come off completely, commercial products like “Good Off” or “AlbaChem” can be used. These are specially formulated to break down screen printing inks. However, be cautious: some chemicals can damage delicate fabrics like jersey or polyester, so it’s recommended to test on hidden areas first. Home remedies like vinegar, lemon juice, and baking soda can also be used, but they are generally less effective than chemical removers.

How to remove print from a Hoodie?

Removing a print from a hoodie can be delicate because it depends on the type of fabric.

• For light screen prints, you can use acetone or nail polish remover, gently rubbing on the print area to avoid damaging the fabric fibers.

• If the print is more stubborn, use a heat press and paper towel to soften the ink may help. Then you peel or rub off the ink.

• Sometimes, a fabric cleaner or specialized print remover may be helpful.

• Keep in mind that not all methods work for every print, so it is always best to test a small hidden area first.

Can you Screen Print on Polyester?

Yes, screen printing on polyester is possible, but it requires careful handling. Polyester is a synthetic, silk-like fabric that does not tolerate high heat well, so special low-cure polyester inks are used that can dry at lower temperatures.

Additionally, pre-treatment or special coating is often applied to the fabric to ensure the ink adheres well and produces a sharp, long-lasting print. After printing, a heat press or flash curing is used to seal the ink into the fabric, so the print remains intact even after washing. If done by experienced professionals, polyester can yield beautiful, durable paints just like cotton.

How to remove Screen Printing from a Shirt?

To remove screen printing from a shirt, the first step is to identify the type of ink used: plastisol, water-based, or direct-to-garment (DTG).

• For plastisol prints, a screen print remover can be effective.

• For water-based prints, using hot water, detergent, and a scrubbing brush can remove most of the ink.

• If the print is new, applying mild heat with a hair dryer can soften the ink, making it easier to wipe off.

• Remember that older prints take longer to remove, and the shirt’s texture or appearance might be slightly affected afterward.

What is a good tension for screen printing?

The quality of screen printing largely depends on the tension of the mesh screen, i.e, how tightly the mesh is stretched. Typically, 20 to 25 Newtons per centimeter (N/cm) is considered an ideal tension range.

• Higher tension allows ink to transfer more cleanly onto the fabric, delivers sharper alignments, and preserves fine details.

• Lower tension can result in blurry prints, especially in designs with small text or intricate details. Professional printers often adjust the tension based on the type of fabric.

For example:

Lighter tension for jersey and tighter tension for cotton to improve ink grip and overall print quality.

Can you Screen Print on Nylon?

Yes, screen printing on Nylon is possible, but it requires special care and expertise. Nylon is a smooth, shiny, and water-resistant fabric, which means regular inks do not adhere well to it.

• Nylon-specific inks and adhesion promoters are used to ensure the ink sticks to the surface.

• Before printing, the nylon fabric may undergo light sanding or surface treatment to improve ink grip.

• After printing, low heat or air curing is used to set the ink without damaging the fabric. Printing on nylon can be challenging, but when done properly, it gives us excellent results

Removing Screen print from Jersey Fabric?

Jersey is a delicate and stretchable fabric, which makes removing screen print from it a sensitive process. Common methods like using a heat gun or chemicals can damage the fabric if not handled carefully.

• The first step is to identify the type of ink used. If it’s plastisol ink, then a plastisol remover is the best choice. Apply a small amount to a cotton swab or soft cloth and gently rub only the printed area. Avoid pulling or stretching the fabric to help its shape.

• If the printer is water-based, removal is somewhat easier. You can use warm water, mild detergent, and a soft-bristled brush, rubbing gently in a circular motion.

• Sometimes, applying mild heat using a heat press or hair dryer can soften the print, making it easier to remove.

• The most important point is to test any holder or remover on a hidden part of the jersey to make sure it does not stain or damage the fabric

Contact us

Final Thoughts:

Screen printing is an art that gives your brand color, depth, and a professional look. If your goal is high-quality, long-lasting prints and large-scale production, screen printing is an excellent choice. However, for smaller

Let’s Bring Your Dream Designs to Life With the Best Quality, True Dedication, and Complete Expertise!Ascension International is not just a clothing manufacturer — we are a trusted partner for your brand. We don’t just print on your garments, we bring your vision to life. With modern machinery,m vast experience, excellent customer service, competitive pricing, and on-time delivery, we offer everything under one roof. Whether you’re launching a new brand, running an existing business, or simply have a creative idea, we’ll walk with you every step of the way. From Plastisol to Glow in-the-Dark, Puff Printing to Foil Print — we specialize in all types of printing. We support you throughout the process from fabric manufacturing to delivering the fully finished product. Now is the time to take the next step — but don’t delay! If you’re looking for premium quality, cost-effective solutions, and comprehensive services, contact us today and start a strong and successful partnership just like hundreds of our satisfied clients. Place your order and watch your dreams beautifully take shape. We’re ready — are you? Let’s create something amazing together.