What is Embossing Effect?

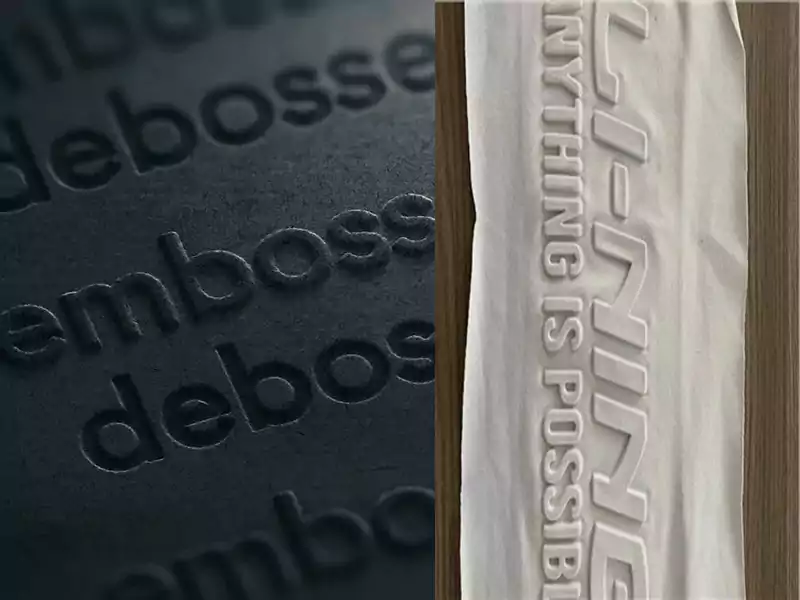

Embossing is a unique, attractive, and high-quality technique through which specific designs, logos, or text are raised and highlighted on various surfaces such as fabric, paper, or leather. In this process, by using heat and pressure with special metal plates (dies), the fabric or other surfaces are pushed upward from inside, as a result of which a three-dimensional (3D) raised effect is created that not only pleases the eyes but also feels different to the touch. The biggest advantage of embossing is that without any ink, only with texture, the design can be shown, which creates an elegant, durable, and luxury look. This technique is especially used in streetwear and fashion wear garments so that the brand may get a separate and unique identity.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Products Collection with Embossing Effect.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Embossing effect technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Embossing effect adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

Although generally embossing is done without any color, but it is also important to note that later on, colorful prints, foil stamping, or stickers can also be added on the raised surface so that the design may look more attractive and dynamic. By applying different colored layers or effects on the same design, it can be made even more unique, bright, and high-end — especially when it is about custom fashion or personalized branding. This very quality makes embossing not only a technical but also a creative art, which is greatly appreciated in the fashion industry.

History and Origin of Embossing

The technique of embossing is centuries old, whose roots are found in Europe’s Middle Ages, when it was first used on book covers to apply designs and official seals. At that time, this process was mostly done on leather, and with hand-made metal plates, some royal symbol or religious text was raised. Gradually this technique also entered the paper industry and was adopted for showing beauty and prestige on books, invitation cards, certificates, and premium packaging. With the passage of time, as the textile industry developed, embossing also stepped into the field of fashion and streetwear. Now this technique is not limited only to formal paper documents but is also used on t-shirts, hoodies, jackets, tracksuits, and other fashion items, where the brand’s logo or specific design is highlighted in raised form without any color. In today’s modern manufacturing environment, embossing is considered a premium feature, which enhances the class, elegance, and recognition of the brand. Today, the importance of embossing has increased more than ever, especially in brands and custom fashion, where people want unique, minimalistic yet impactful designs. This technique not only provides visual beauty but also gives a new and lasting angle to brand identity. That is why embossing is not considered only a design tool but also a creative and business strategy.

Process of Embossing

The process of embossing seems simple but technically is very sensitive and full of intricacies, in which correct temperature, pressure, and dies must be used. In this technique, first the specific design, logo, or text is prepared on a computer, which is later engraved on a metal die or brass plate. This die consists of one male and one female mold, between which the fabric or leather-like material is placed. Then with the help of a specific machine, these two molds are heated and pressed with heavy pressure, as a result of which the design rises on the fabric or other surface. This process is usually done on materials like cotton, leather, denim, or microfiber that have the ability to bear heat and pressure. During embossing, temperature, time, and pressure are balanced in such a way that neither the material gets damaged nor the design becomes blurred. In the modern age, hydraulic and heat press machines are used, which with high accuracy provide a uniform raised effect. Further, if the brand wishes, colorful foil, prints, or shining stickers can also be applied on the raised surface so that the design becomes more prominent and attractive. Sometimes embossing is also combined with digital printing, flex, or foil stamping so that both depth and beauty may be included in the design. In fashion garments, handbags, leather jackets, and custom clothing this technique is especially used so that every product gains a premium and unique identity.

Different Types of Emboss Printing

Embossing is a creative process, which is not limited to only one style but is used in various forms and techniques, so that every design or brand may be given a specific prominent look according to its need. The choice of these types is made based on what kind of effect, texture, or presentation is required, especially in fashion or luxury products. The purpose of each type of embossing is not only beauty but to give the product such a character that can be felt in the hand and pleases the eyes. That is why today every brand, according to its mood and requirement, selects from these types of embossing.

• Blind Embossing: This is the simplest and classic type in which no color, foil, or ink is used. Only the raised texture itself shows the design. This technique is mostly preferred for minimal and elegant style, such as fashion wear brands’ logos or specific symbols.

• Registered Embossing: In this, embossing is registered at the exact place with a print or colored design, meaning first the design is printed and then exactly that place is raised. This type creates a more attractive and clear effect, especially when the logo or text needs to be highlighted.

• Multi-Level Embossing: In this technique more than one depth or level is created so that more dimension and depth may be felt in the design. This is often done on premium garments or custom jackets, where the brand wants to create a special artistic effect.

• Sculptural Embossing: This is the most artistic and complex type of embossing, in which the design is raised in three-dimensional sculptural style. For making faces, animals, or symbolic shapes close to reality, this type is used. It has high demand in high-class fashion or leather items.

• Combination Embossing: In this embossing, foil stamping or printing is also included. Its purpose is to create a more attractive, shiny, and attention-grabbing design. Especially in women’s fashion items, labels, or luxury brand tags this is commonly used.

Materials Used for Embossing

Embossing is a sensitive and specific technique that is not possible on every type of material. Only those surfaces or fabrics are considered suitable that can bear heat and pressure, and that have enough flexibility so that with the die’s pressure the raised design may retain its shape. In the clothing world, embossing is mostly done on fashion wear, streetwear, or leather-based products — such as cotton blends, denim, twill, leather (real or synthetic), cotton jackets, and canvas-like materials. Pure cotton or light knit fabrics like jersey or single jersey are often not suitable because these materials lose their structure under pressure or cannot create complete raised effect. Similarly, polyester or sports fabrics, since they are heat-sensitive and especially made for sublimation, embossing is usually not possible on them or can be done only in special conditions with specific methods — but generally embossing on them is not recommended. Since in our field we work on fashion garments, we select only those materials that are practically suitable and durable for embossing. For good results, not only material quality is important but also its thickness, structure, and resistance to heat are kept in mind. If you have any specific fabric in mind, we first test the possibilities of embossing on it and then provide you the service so that not only the print looks beautiful but also lasts for long — this is our identity.

Advantages of Emboss Printing

Embossing is that printing technique which creates elegance in simplicity and dignity in silence. Its biggest quality is that it highlights any design without color, ink, or noise — only through the raised texture, which not only pleases the eyes but also gives a special feeling on touch. This very uniqueness makes it especially ideal for fashion wear, high-end leather products, and branded garments. The most important advantage of embossing is that it highlights the premium identity of the brand. When a customer sees and feels a raised logo or design on a product, he immediately considers that product as something special, expensive, and of quality. Along with that, this technique is long-lasting because there is no risk of any color peeling or fading — the design always remains in its structure. This technique is also beneficial for those brands that prefer minimalist style, where depth lies in few words or symbols. The second advantage of embossing is that it can also be combined with other techniques (like foil stamping or digital printing), by which more creative and eye-catching results can be achieved. Further, embossing can also be environmentally friendly because often in this, ink, chemicals, or additional printing materials are not used — only through pressure and heat the design is raised, which makes it simple yet effective. In short, if you want your product to speak without speaking, then embossing is that language which expresses quality, brand, and elegance all together.

FAQ'S

What is emboss printing?

Emboss printing is a technique in which a specific design or logo is raised and shown on fabric or paper, meaning the design is felt above the surface.

Which machines are used in emboss printing?

Generally heat press machine, high-pressure embossing machine, or die-based machines are used.

Can emboss printing be done with colors as well?

Embossing basically creates texture or raised effect, however sometimes it is also combined with foil stamping or ink so that colors may also be included.

Can this printing technique be used on children’s clothes?

Yes, but with special care for softness and safety, because hard raised designs may scratch children’s skin.

Can emboss printing be done on clothing?

Yes, emboss printing is especially done on hoodies, t-shirts, and other fashion items so that the design may be highlighted and made premium.

Is a separate die required for emboss printing?

Yes, for every design a special die is prepared which presses on fabric or material and creates the raised effect.

How much is the cost of emboss printing?

The cost depends on your design, order quantity, and machinery, but compared to ordinary printing it is relatively expensive.

What is the lead time in emboss printing?

Generally 7 to 15 days, but it depends on the order quantity and complexity of design.

What is the difference between embossing and debossing?

In embossing, the design rises (comes upward), whereas in debossing, the design sinks inside (goes downward).

Is emboss printing more expensive than screen printing?

Yes, because in it die making, heat, and pressure are used, so it is more costly compared to other printing techniques.

Is emboss printing done on clothes for export abroad?

Yes, especially on premium brands and high-end export items this technique is used so that the product may be made unique and attractive.

On which fabrics can emboss printing be done?

This printing technique is generally done on thick and stiff types of fabrics such as fleece, cotton, leather, and PVC coated fabrics.

How many pieces can be embossed with one die?

A good-quality die can be used for thousands of pieces, provided it is properly maintained.

Is there any minimum order condition for emboss printing?

Most manufacturers keep 100 or 200 pieces as MOQ (Minimum Order Quantity), but it depends on each company.

Can emboss printing be done at home on fabric?

No, because for it special machines and pressure are required which are not available at household level.

Does emboss printing remain after washing?

Yes, if it is done professionally it remains for many washes, provided proper care is taken.

Is emboss printing environmentally friendly?

Generally this printing is not considered environmentally friendly because in it heat, chemical coatings, and energy are used more.

What is the difference between embossing and 3D printing?

In embossing the design itself rises on the fabric, whereas in 3D printing additional material is used, which makes the design appear 3D.

Does emboss printing affect the weight or warmth of the fabric?

Yes, if thick die or material is used then it may make the fabric feel a little heavy or warm.