What is DTF stickers?

(The latest printing technique which turns your design into reality on every color, every fabric).

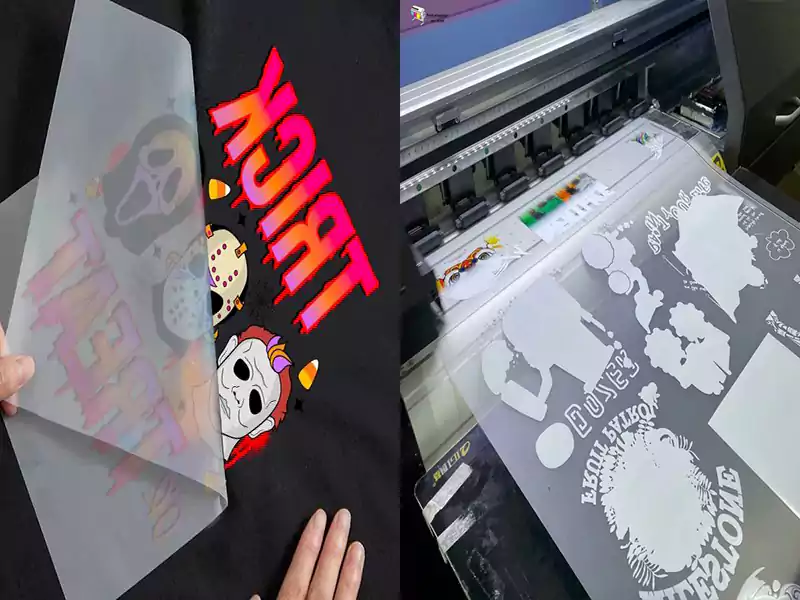

Have you ever thought that those beautiful, colorful, and fine-detailed designs finally how come onto clothes? Especially when they look as if in the form of a sticker? So sir, this is the wonder of DTF printing! DTF, meaning Direct To Film, is a modern printing technique in which a sticker-like design is printed on a special type of film, and then with the help of heat and pressure, it is transferred onto any fabric. The special thing about this method is that it not only provides bright and long-lasting colors but also prints even the smallest of designs with extreme elegance.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Products Collection with DTF Stickers.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in DTF Stickers technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how DTF Stickers adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

You may estimate the popularity of DTF printing like this: experienced clothing manufacturer Ascension International now prefers this technology. To strengthen the brands of its customers, it includes DTF printing in its main services. This technology is the best way to turn your every idea into reality. You may estimate the popularity of DTF printing like this: experienced clothing manufacturer Ascension International now prefers this technology. To strengthen the brands of its customers, it includes DTF printing in its main services. This technology is the best way to turn your every idea into reality.

DTF has superiority over the rest of the printing methods in many respects, such as:

● It can be applied on almost every type of fabric

● The beauty of colors remains intact

● Even after repeated washing, DTF heat transfer prints do not get damaged

● High quality is achieved at low cost

If you want to know how does DTF printing work or is DTF printing good quality, then be happy because on this page we will tell you everything that is in your heart. Whether you want to start a small-scale business of selling clothes or are dreaming (bigger), this technique can prove to be a game changer for you.

History of DTF Printing – That story of innovation in the world of printing, which grew during the time of the Corona pandemic and today has become the identity of every brand.

DTF Printing (Direct to Film Printing) started in the early 2000s when digital printing technology was rapidly progressing. This technology initially entered garment printing on a limited scale, where inkjet printers began to be used on special film sheets. In the beginning, DTF printing was considered an alternative method (DTG – Direct to Garment or Sublimation Printing) as a cheaper but effective alternative. But soon it became clear that this method was more effective in many respects, especially for those companies that wanted to print on different types of fabrics – such as cotton, polyester, blends, or even denim. But then came that time when the world was surrounded by a global pandemic like Corona. Supply chain disruptions, closure of physical stores, and the need for fast, cheap, and effective printing raised DTF printing to a new height. After that, it was not only a technique but became a revolution for small businesses, online brands, and custom merchandising. In that era, placing beautiful prints on garments through stickers became a popular trend.

*Ascension International* not only adopted this technique but also made it an important part of its standard production. The special thing about DTF was that it did not require pretreatment, and once the design was printed on film, it could easily be applied to many kinds of fabrics – that too with high detail and bright colors. During 2021 and 2022, as DTF inks, films, and powders improved, this technique became the first choice of garment manufacturers, brand owners, and printing houses worldwide. Today, DTF is not only a technique but a complete branding solution, beneficial for every person or company who wants high-quality prints with quality, flexibility, and low cost.

Process of DTF Printing (Direct to Film Printing)

1. Design preparation

First of all, the design or graphic which has to be printed is prepared. This design is made on a computer through software, where details of different colors, sizes, and graphics are included. In this stage, preparing the design correctly is very important so that after printing it looks clear and neat.

2. Printing process

In this stage, the prepared design is printed on a special film. This printing process is done through a DTF printer, which is capable of printing very high-quality images and colors. During printing, the intensity and accuracy of colors are ensured so that the result is clearer and more vibrant.

3. Layer of polymer powder

After printing, the film that is prepared has a layer of polymer powder applied on it. This powder helps to hold the printed colors firmly and ensures their longer durability. The powder is sprinkled on the film in such a way that it spreads evenly on all printed parts.

4. Setting the powder through heat

Now, this film is placed in a heating machine, where with the help of heat the polymer powder is set well on the film. This process ensures that the design can be preserved longer and later appears glossy.

5. Cutting the sticker

In this stage, the printed film is cut according to its shape and size so that it can be used on a garment or surface. During cutting, care is taken that no part of the sticker is wasted and its shape remains correct.

6. Applying the sticker to the garment

Finally, the prepared sticker is applied to the required garment or surface. This stage is also very important because the sticker has to be placed in the right position so that it fits beautifully and its color and design remain clear.

At our company *Ascension International*, we, using this modern and effective technique of DTF printing, provide our customers with the best quality products. In the completion of every stage, we work with extreme care and effort so that you get the best results.

Care & Instructions

● Always wash clothes with DTF stickers by turning them inside out so that the print remains safe.

● Washing by hand is better instead of machine wash, but if you have to wash in machine, wash on gentle cycle.

● Use cold or lukewarm water instead of hot water.

● Use detergent that does not contain bleach or harsh chemicals.

● After washing, dry in shade; drying in sunlight can reduce sticker shine.

● While ironing, do not apply directly on sticker; put a cloth on top or avoid the sticker area.

Precautions to increase the life of DTF sticker

● Do not wash clothes repeatedly; unnecessary washing can damage sticker quickly.

● Do not rub or scratch sticker again and again; print can peel off.

● Do not fold or keep clothes in such a way that sticker layers stick to each other.

● Never use hot air dryer or high heat setting iron.

● DTF sticker is considered more durable on thick or soft fabrics; applying on very thin or rough fabrics is less effective.

Types of DTF Inks

DTF printing is not only according to process or film, but also has many advanced types according to colors, finishing, and effects, including fluorescent, metallic, glow-in-the-dark etc. These types are specially used for brands, fashion designers, and unique prints. Below, some important and advanced types are explained in detail:

1. Fluorescent DTF Printing

This type is used for sharp and bright colors which are shinier and more vibrant than normal colors. Especially used in children’s clothing, party wear, or fashion garments.

Features:

● More visible in daylight

● Neon effect

● Available in limited colors

2. Glow-in-the-dark DTF Printing

These stickers glow in darkness. When placed in light, they absorb light and later emit light in darkness.

*Uses:*

● Night party shirts

● Children’s clothing

● Event special items

3. Metallic DTF Printing

This creates shiny and metallic effect. Available in colors like gold, silver, bronze.

Uses:

● Logos

● Luxury brands

● Sports or streetwear

4. Reflective DTF Printing

This type shines when light falls on it, like print glows when hit by car headlight.

Mostly used in:

● Running gear

● Night wear

● Safety wear

5. Watercolor Effect DTF Printing

In this, print looks like watercolor painting. Gives soft and blurry effect, liked in artistic brands. These modern types are nowadays becoming very popular in global brands and high-fashion industry. Ascension International has expertise in all these types and prepares every kind of print according to customer’s choice.

FAQ'S

What is DTF transfer?

DTF transfer is a special printing film on which color and powder are applied to transfer design onto fabric. This film is applied to fabric through heat press.

Is the quality of DTF printing good?

Yes, DTF printing not only gives clear and vibrant colors but also lasts for a long time, provided that care is done properly.

Can DTF sticker be applied on every type of fabric?

On most fabrics it can be applied, especially works best on cotton, polyester, and their blends. But on some special fabrics, it is better to test first – such as nylon, waterproof fabric, high-stretch spandex, silk, leather, and PVC-coated fabrics.

Can I also get a free sample with a design or logo?

Yes, upon your request, we can also provide samples with a specific design or your brand’s logo. In such cases, minor development charges may apply, but these charges will be refunded if the order is confirmed later.

What is the Shipping Duration?

Our company is committed to fast delivery. In normal circumstances, once your order is ready, the parcel reaches you within 3 to 6 days. This is part of our fast turnaround service, which sets us apart from other manufacturers.