What is Cracked screen Printing? A Vintage Look for a Modern Fashion Wave

In the world of fashion, some trends capture hearts with their uniqueness. Crack printing is one such special printing technique that gives the appearance of fine cracks on printed designs, as if an old painting has started to peel with time. This “worn-out” style is now recognized as a vintage

and retro look in modern fashion, especially popular among youth and streetwear enthusiasts. Whether it resembles weathered walls or aging textures, this look is intentionally crafted and not accidental.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

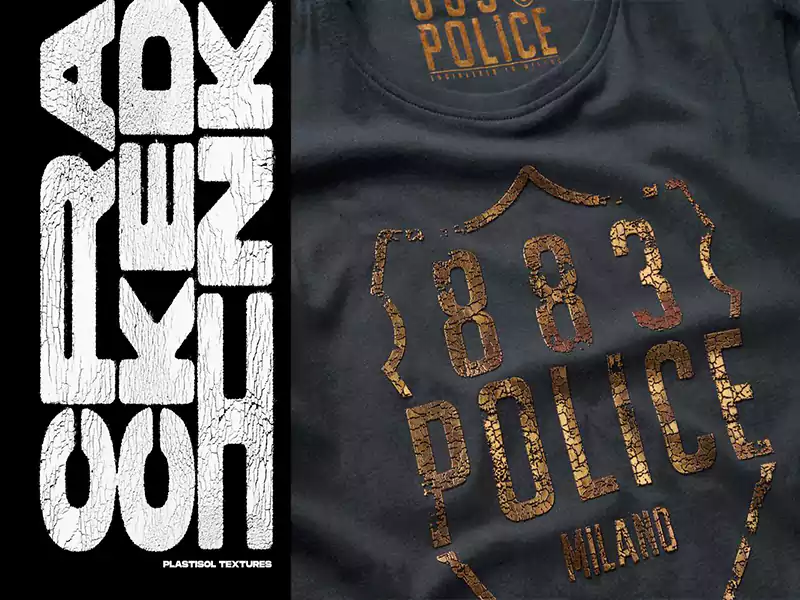

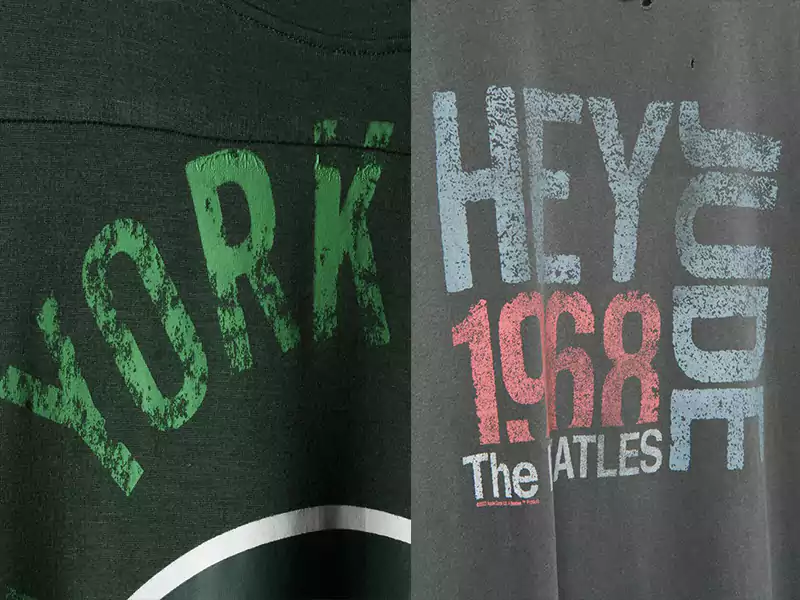

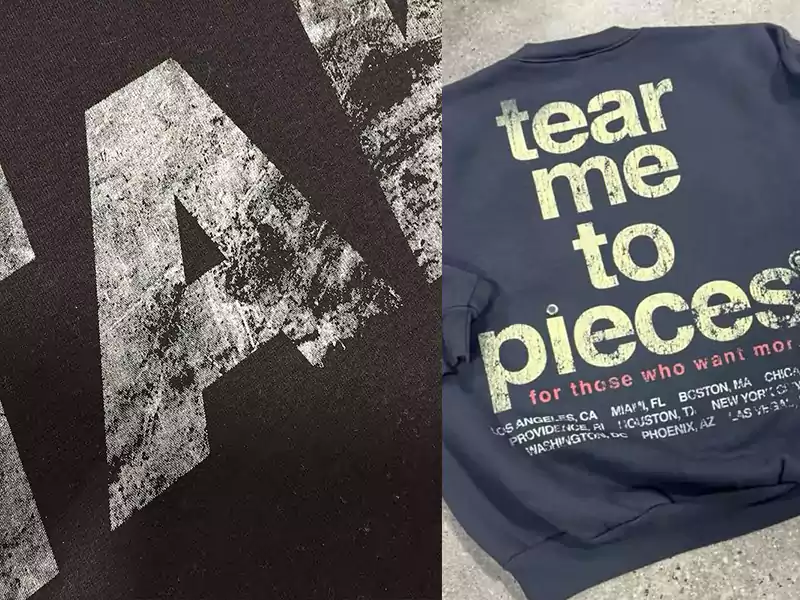

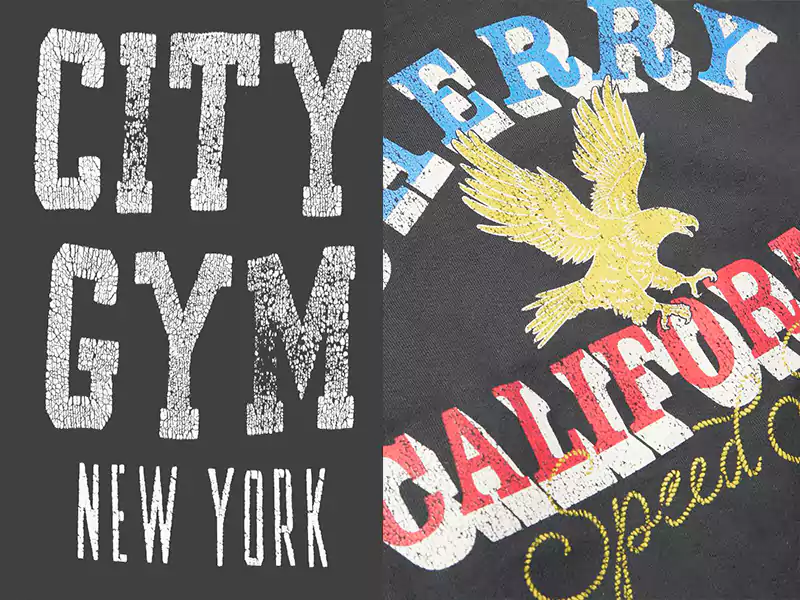

From Concept to Perfection Explore Our Products Collection with Cracked screen Printing.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in cracked screen printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how cracked screen printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

Crack printing is not just random damage—it’s a deliberate, stylish effect created through a specific Screen printing method. Special inks, heat, and technical skills are used to achieve the “cracked effect.” Interestingly, while cracks on clothing are usually seen as damage, in crack printing, they become a mark of beauty. This printing style is ideal for those who want something different from traditional designs, something artistic and bold. Whether it’s band merchandise, graphic t-shirts, or vintage-look hoodies-crack printing adds a unique soul to everything.

The History of Crack screen Printing - A Style Born from Cracks:

The history of crack printing is not centuries old, but its look feels like a nostalgic throwback. This printing technique emerged primarily in the 1980s and 1990s in the fashion world, when rock bands, street artists, and people associated with punk culture began wearing clothes that appeared more raw and edgy, a visual rebellion against conventional styles. Crack printing began as an experimental branch of screen printing. Some printers use thick ink and high heat, and notice that the ink naturally cracks as it dries, giving a distressed effect. Initially, these cracks were seen as flaws, but soon fashion designers turned them into an art style. What started as an accident evolved into a trend. This technique first gained traction in the U.S. and Europe, especially in street fashion cultures of cities like New York, London, and Los Angeles. Graphic designers and bands embraced it as a part of their identity. Today, crack printing is not limited to niche groups – it’s now a fully recognized style in the global fashion industry. Streetwear brands, high fashion labels, and even online custom printing platforms have adopted crack printing. The style is especially popular in Japan, South Korea, the U.S., and Europe.

Why Choose Us?

When it comes to quality, innovation, and personal style, Ascension International is more than just a garment factory. Ascension International is not just an ordinary garment manufacturing facility; we have positioned ourselves as a complete brand partner. We do not just produce garments based on our clients’ preferences and requirements; we also offer custom printing and custom design services tailored to their taste, identity, and creative vision. Even delicate techniques like crack printing are executed under an expert’s supervision with full technical precision, ensuring that each print delivers the exact cracked aesthetic that’s expected. Our company not only houses a professional and high-quality crack printing setup, but we also work with a variety of modern and creative printing techniques, including:

• Thermochromic Printing:

A temperature-sensitive technique that changes color with heat.

• Discharge Printing:

Used for soft and light prints on dark fabrics.

• Silicone Printing:

Gives a raised, rubber-like texture.

• DTG (Direct-to-Garment) Printing:

A modern digital method for detailed, colorful designs.

• Laser Printing:

A modern technique of printing, with the help of lasers.

• Chenille Embroidery:

Raised embroidery using thick and soft threads.

• Embossing:

Adds a raised texture of fabric.

• Distressed Embroidery:

Offers a vintage and traditional look.

• Reflective Sticker Printing:

Glows under light.

• Vinyl Sticker Printing:

Ideal for durable and clear sticker applications.

• UV Printing:

Produces long-lasting colors using light.

• Glitter Printing:

Adds shine and sparkle to garments.

• Flock Printing:

Creates a velvet-like feel.

• Sublimation Printing:

Primarily used on polyester fabrics.

• DTF (Direct-to-Film) Printing:

For transparent and intricate prints.

• Screen Printing:

One of the most popular and durable techniques.

• Rhinestone Design:

A dazzling technique where sparkling stones are applied to garments.

At Ascension International, our services go far beyond garment production. We provide complete client support, including:

• Fabric selection

• Design consultation

• Sampling

• Low minimum order quantities

• Timely production

• Guaranteed quality

• Fast shipping

Our mission is not just to create garments-but to give your brand a new identity. And this very passion is what sets us apart.

How the Magic of Crack screen Printing Works: A Step-by-Step Process:

Crack printing is not just an ordinary printing technique- it is an art form that gives every garment a unique, vintage character. Let’s explore how this beautiful, crackled effect is brought to life:

1. Fabric Selection:

First, a fabric is carefully chosen that is suitable for crack printing. Typically, cotton or cotton blended fabrics yield the best results.

2. Design Preparation:

Next, a special design is created either according to the client’s preference or with the assistance of our creative team experts, ensuring that it looks stunning with the crack effect.

3. Preparation of Special Crack Ink:

For crack printing, a specific type of ink is used that naturally forms cracks as it dries. This ink is thicker than regular printing inks and has unique chemical properties.

4. Important Chemicals Used in Crack Printing:

The special ink used in crack printing is typically a plastisol-based thermoplastic ink, which contains crack-enhancer additives.

5. Plasticizers with PVC (Polyvinyl Chloride):

This key component provides a balance between flexibility and shrinkage. When the ink undergoes the curing heat process, it contracts and forms cracks on the surface.

6. Screen Preparation and Printing:

The design is transferred onto a screen and printed onto the fabric, similar to traditional screen printing-except that here, a special crack-effect ink is used.

7. Curing Process (Drying):

This is the most crucial stage. The printed fabric is dried at a specific temperature to allow the ink to naturally crack. The temperature, curing time, and ink layer thickness all determine how prominent and artistic the crack effect will appear.

8. Final Touch and Quality Check:

Once the printing is complete, each unit is thoroughly inspected to ensure the crack effect is balanced, artistic, and durable. If necessary, minor finishing is also done to enhance the print’s longevity. This entire process is carried out at our company using advanced machinery and under the supervision of experts, ensuring that every piece perfectly blends art and quality.

Care and Precautionary Instructions for Crack Printing:

• Wash in Cold Water:

Always wash garments with crack printing in cold or lukewarm water. Hot water can soften the ink and ruin the natural, cracked style.

• Wash Inside Out:

It is essential to turn the garment inside out before washing to protect the print from direct rubbing or pressure from water during the wash.

• Use a Mild Detergent:

Use detergents that are based on soft chemicals. Avoid using bleach or harsh chemical-based detergents as they can damage the print.

• Handle Machine Washing with care:

If machine washing, select a gentle cycle. High speed or heavy cycles can cause the crack ink to break or peel.

• Avoid Using a Dryer:

Do not use a drying heat cycle or tumble dryer. Instead, let the garment air dry naturally in the shade to prolong the ink’s lifespan.

• Be Careful While Ironing:

Never iron directly on the crack print. If ironing is necessary, turn the garment inside out and use a low heat setting, or place a cloth over the print before ironing.

• Avoid Rubbing or Scrubbing:

When washing, do not rub or scrub the printed areas, as this can worsen the cracks and damage the design.

Following all these instructions not only helps maintain the beauty of the print but also gives the customer a strong sense that we deeply care about quality and detail. If you want to create a distinctive identity in your branding or personal collection, crack printing can be a fantastic choice. However, to truly take advantage of it, quality, expertise, and careful maintenance are all essential, and you will find all of these at Ascension International.

FAQ'S

Does crack printing get damaged after washing?

Crack printing is generally quite durable, but if not cared for properly. It can deteriorate or crack further. To preserve the crack-printed garments, it is essential to wash them inside out using cold water. Hot water or aggressive washing can cause the cracks to expand. Similarly, for drying in the shade, as excessive heat or tumble drying may shrink the print. With proper care, the lifespan and appearance of crack printing can be maintained.

Do the chemicals used in crack screen printing damage the fabric?

The chemicals used in crack printing are generally safe and do not harm the fabric. However, if low-quality chemicals are used, it could lead to issues like color fading or fabric stiffness. At Ascension International, we prioritize both customer health and environmental safety. All chemicals used for crack printing at our company undergo rigorous quality checks to ensure they are safe for both your clothing and that your preferred crack printing is achieved without damaging the fabric. Our expert team ensures that quality and safety and maintained throughout every process.

Can vinyl or DTF prints crack as well?

Vinyl and DTF (Direct to Film) prints differ from crack printing, but over time and with heavy use, they can also start to crack-especially, especially if garments are washed improperly or worn during rigorous activities. Both printing methods use strong adhesives, but under pressure or high temperatures, they may develop cracks. Compared to crack printing, these techniques are slightly less maintenance, but care is still important.

Does crack printing affect the breathability of the fabric?

When ink is absorbed into the fabric during the crack printing, it can sometimes impact the fabric’s breathability. However, this effect largely depends on the type of printing technique used and the nature of the fabric itself. With advanced printing techniques and the use of high-quality chemicals, crack printing maintains the fabric’s breathability. Even with the cracked effect. If you prefer lightweight and comfortable garments, it’s important to ensure that the ink application is not too heavy and that the fabric’s air flow remains intact.

Is crack printing only used on graphic t-shirts?

No, crack printing is not limited to just graphic t-shirts. This technique can be applied to a wide range of garments, such as hoodies, tracksuits, jackets, and even uniforms for cafes or teams. One of the most appealing aspects of crack printing is its ability to provide a “desired worn” and unique vintage look, which works well on many types of apparel. Besides t-shirts, it also looks great on accessories like caps and bags, especially if you are going for a fashionable or retro aesthetic.

Does crack printing shrink or fade with repeated wear?

If crack printing is done properly and maintained well, it generally does not suffer significant damage even with repeated wear. However, with heavy use, the cracks may becomes more pronounced. It is important to protect crack-printed garments from excessive heat and harsh washing to maintain the durability of the print. That said, the fabric quality and print durability largely depend on how well you take care of the garment.

Can I get my custom design printed using crack printing?

Yes, you can absolutely have your custom designs made with crack printing, and it’s a very popular option. At Ascension International, we provide fully customized crack printing services based on your specific needs. You can submit your graphics or messages, and we’ll convert them into beautiful crack print designs. Our expert designers and printing team ensure your design is printed with top notch quality, enhancing your brand’s identity while meeting your expectations.

Is the crack print effect consistent every time, or is each print unique?

Crack printing is a unique process that results, each print looking slightly different. Since the cracks are intentionally created, the texture and pattern of each print can vary slightly, giving every shirt or graphic a distinct appearance. Therefore, every crack print is unique, and the look varies slightly each time. This uniqueness and standout fashion appeal are major advantages for customers seeking something special and different.

Why is crack printing more expensive than regular printing?

Crack printing is generally slightly more expensive because it involves a specialized process that requires additional steps. It demands the use of specific chemicals, techniques, and more time. This printing method can be more labor intensive and costly due to factors like the nature of the design, the use of high quality chemicals, and the careful management of the cracking effect. Despite the extra cost, crack printing offers a unique and attractive style, making it a worthwhile experience for customers who appreciate its distinct benefits.

Contact us

If you want to present your brand uniquely, Ascension International is ready to bring your dreams to life. We don’t just manufacture garments, we transform your ideas into art. Whether you are looking for crack printing, thermochromic, DTF, sublimation, or embroidery techniques, we specialize in every style. Our services include free mockup design, custom designing, custom printing, brand labeling, and custom packaging tech pack designing, sampling, and full production. Our goal is not just to deliver a product but to turn your brand vision into reality. So don’t wait! Contact us today and place your order with confidence for your next project. Your brand, our expertise — the beginning of a successful story.