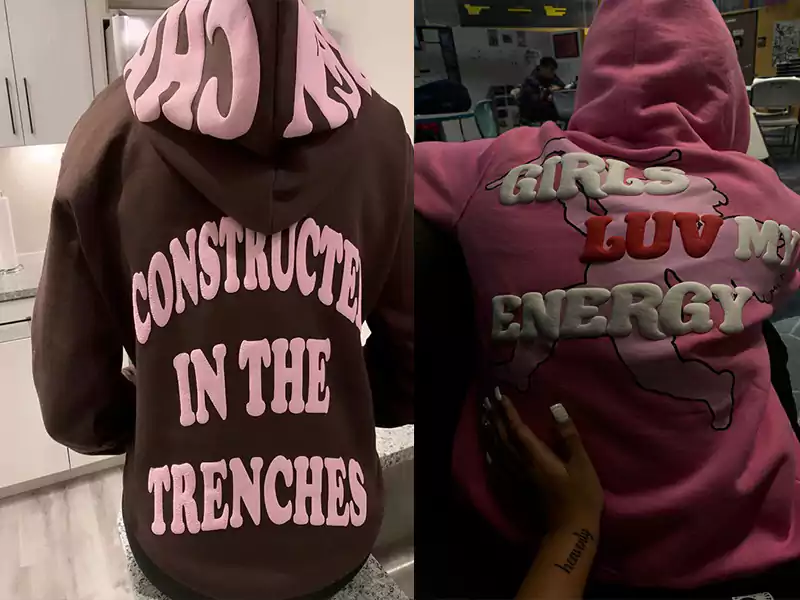

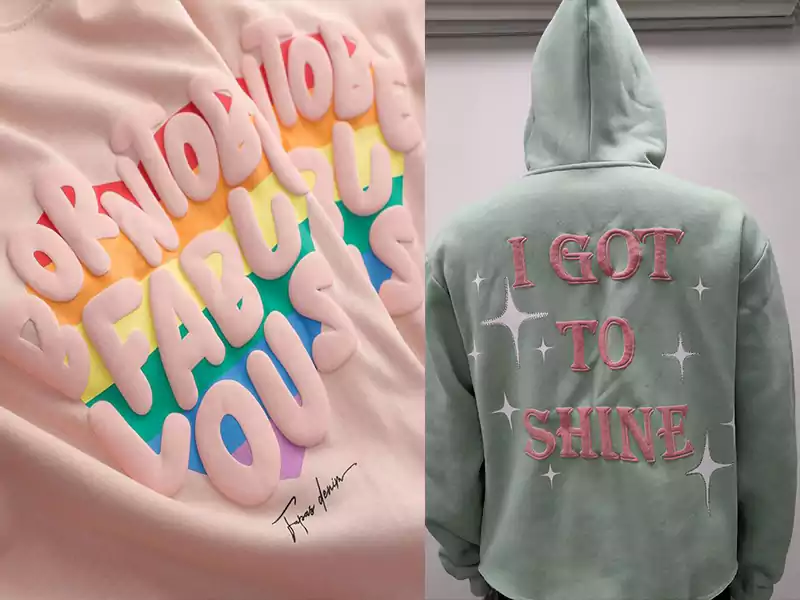

What is Puff Printing?

Puff print, which is an innovative and artistic printing method in the fashion and textile industry, is extremely popular especially because of its three-dimensional raised texture. In this technique, a special type of ink is used which expands with the process of heat, as a result of which a soft, raised, and attractive design appears on the fabric. Puff printing is not only a printing technique but also an art which makes your T-shirts, hoodies, or any fashion article not only eye-catching but also gives a unique feeling to touch. It becomes especially popular when brands or designers want to include unique texture, depth, and style in their garments.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Products Collection with Puff Printing.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Puff Printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Puff Printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

Its specialty is that puff print is not only visually wonderful but also comfortable to wear, because it fully harmonizes with the surface of the fabric. That is why many famous brands nowadays adopt it as their signature style. Whether it is about a bold logo, an interesting graphic design, or a simple yet prominent text — puff print gives your garments a separate identity and leaves a lasting impact in the mind of the consumer.

History of Puff Printing – A Story of Artistic Raise

The beginning of puff printing happened in the 1970s when the textile and fashion industry started searching for new dimensions in the field of printing. In that era, clothes only had simple prints – smooth, flat, and sometimes even boring. But as soon as the demand for three-dimensional effects increased, an experiment was done: the concept of “Raised Print” was born. And thus puff printing came into existence – a technique which turned ordinary print into a blooming, lively piece of art. Initially, this technique was used in streetwear and branded T-shirts so that people could recognize from afar which brand’s logo it was. But soon its beauty also embraced fashion, high-end brands, and artistic collections. Imagine: when a simple word “LOVE” blooms with puff print and comes in front, it creates an emotional effect — as if words are not only written, but also “felt.” And this is the soul of puff printing: a design which is not only seen, but also touched and felt!

Step-by-Step Process of Puff Printing

1. Design Preparation: The first step of puff printing is to make a beautiful and clear design. This design is usually prepared in software like Adobe Illustrator or Corel Draw. Remember, since later the print will “expand,” very thin or delicate lines are not suitable – it is better that the design has thick and filled areas so that the puff effect becomes clear.

2. Screen Making: When the design is finalized, then it is transferred to a special mesh which is called a “screen.” This screen is prepared with photo-emulsion method so that the print comes out only from the required design area. This is the same traditional method which is used in screen printing.

3. Selection of Puff Ink: Now comes the turn of puff ink, which is the soul of this process. This is a special type of ink in which “expanding agents” are included. When it is heated with heat press or hot air, this material expands and gives a raised three-dimensional effect. Inks are available in different colors.

4. Printing Process: Now this prepared screen is placed on the fabric and puff ink is applied onto the fabric with pressure through the screen. This process can be done by hand (manual screen printing) or by machine (automatic screen printing), selection depends on production size and budget.

5. Curing with Heat: This is the most important stage! Now the fabric is heated at a special temperature (generally 320°F or 160°C) through “heat tunnel” or “heat press.” This is the magical moment when puff ink expands and the design takes a wonderful three-dimensional form. If temperature or time is not correct, then the puff effect is not fully formed.

6. Final Inspection: Each printed item is finally checked that there is no cracking or uneven raise in ink. If everything is correct, then only the product is sent forward.

Is Puff Print Automatic or Manual?

Puff printing can be done both ways:

● Manual Printing: Adopted for small units or specific color demand. Skill is required.

● Automated Printing: For larger quantities and big orders, automated machines are used which provide uniform quality and speed.

Types and Different Methods of Puff Printing

Puff printing is not a single limited process but rather a world full of variety and creativity, which includes different types and techniques. This means puff printing is not achieved by only one method, but it can be obtained through different materials and technologies. This is the feature which distinguishes it from other printing techniques. Each type of puff printing has its own unique personality. As technology is progressing, the styles and possibilities of puff printing are also expanding. Earlier only hand screen print was done, now digital vinyl sheets and thermal reactive prints have made it even easier and full of variety.

Traditional Puff Printing: This is the classic method in which special puff ink is used. When this ink passes through heat press or heat conveyor, the agents present in it expand and create a 3D bubbly texture. This method is mostly used with screen printing.

Puff Vinyl Heat Transfer: A modern and fast method — in this pre-cut puff vinyl sheets are used which are stuck on clothes through high temperature heat press. These vinyl sheets expand with heat and give a thick, soft, and raised surface. This method is especially popular for custom clothing, fashion shirts, and logo prints.

Puff Effect using DTF Stickers:

Although DTF (Direct-to-Film) mainly gives a flat and smooth surface, but some special types of DTF printers and films are also available in which thermal puff effect can be added. This new trend is now coming as a hybrid printing style, where DTF print and puff effect are combined to create dramatic depth and texture.

Hybrid Puff with Embroidery / Foil / Glitter:

Some designers combine puff printing with other elements to make it more interesting, such as: puff print + embroidery, puff print + glitter print, puff print + foil print, puff print + rhinestone. These types are especially used in branded garments and high fashion garments where uniqueness and luxury are necessary.

Care and Precaution Instructions of Puff Printing

Puff printing, because of its special raised texture, is a delicate yet attractive printing technique. If it is not cared for properly, it can get damaged soon, lose its puffed shape, or start cracking. Below we have mentioned some important instructions so that your puff printed clothes can maintain their beauty and quality for long:

1. Washing Instructions

● Always wash puff printed clothes by turning them inside out so that friction on print is less.

● Better to wash in light cold or lukewarm water. Hot water can reduce the expansion ability of print or it may flatten.

● Use mild detergent. Bleach, harsh chemicals, or strong cleansers can damage puff print.

● If machine wash is allowed, wash only on delicate or gentle cycle.

2. Drying Instructions

● Try to dry the clothes naturally in air (air dry).

● If it is compulsory to use dryer, then run dryer at minimum temperature and keep fabric inside out.

● Drying in strong sunlight can fade the color of print.

3. Ironing Precaution

● Do not iron directly on puff printing.

● If ironing is necessary, turn the fabric inside out or put a cloth over the print and iron on low temperature.

● Ironing at high heat can melt the print or make it lose its puffed shape.

4. Other Precautions

● Avoid chemical cleaning (Dry Clean), unless clearly allowed.

● Do not keep puff printed clothes wet or damp for long, because fungus or bad smell can develop in print.

● While folding, try not to make crease over the print. Better is to hang them.

If you follow these simple yet effective instructions, your puff printed clothes will look new for long. Proper care not only keeps the print beautiful but also increases the overall life of the garment.

FAQ'S

What is Puff Printing and how does it work?

It is a technique of screen printing in which a special type of ink is used which becomes raised and prominent when given heat.

Is puff printing durable?

Yes, this technique is considered durable, provided correct curing time and temperature are maintained.

Why is puff printing more costly compared to other prints?

Because the ink used is expensive and curing process is also precise, therefore its cost can be higher.

How to remove puff print from shirts

The method to remove puff print from shirts is almost the same as hoodie. First heat the print, then slowly rub and try to remove it. In some cases, complete removal is not possible and the shirt can get damaged, therefore it is better to get this work done by some expert.

Does puff print get damaged after washing?

If washed correctly, puff print lasts for long. Very hot water or harsh scrubbing can damage it.

What is the difference between puff print and normal print?

Puff print gives a three-dimensional (3D) look while normal print is flat.

Does puff printing increase the weight of shirts?

Very little difference occurs, but in large or heavy designs the weight can increase slightly.

Can puff printing be done on all fabrics?

Puff printing works best on cotton or cotton-blend fabrics. On synthetic fabrics like nylon or polyester, the result may be weak.

Can puff printing be done by hand or is machine necessary?

This technique is usually done through screen printing machine, because consistent heat and pressure are necessary.

Is puff print felt inside the garment?

No, it only raises on top of the fabric, inside the fabric remains smooth.

Does puff print keep clothes breathable?

The area with puff print becomes slightly thick, which can reduce breathability, especially if the print is large.

What is the ideal curing temperature for puff printing?

Generally 320°F (160°C) curing temperature is suitable, but it also depends on the type of ink and fabric.

How to wash puff print hoodie

For washing a hoodie with puff print, the most important thing is to wash it inside out. Use mild detergent in lukewarm or cold water and wash on “delicate mode” of washing machine. Better is to wash the hoodie by hand so that puff print does not get damaged. Do not dry it in sunlight but hang it upside down in shaded place.

Which ink is used for puff printing?

Puff ink is generally made by mixing puff additive into plastisol base, which raises at high-temperature curing.

Does puff printing make colors dull?

No, if ink ratio is correct then colors look clear and bright. However, too much additive can fade the color.

How to remove puff print from hoodie

Removing puff print can be difficult because it is firmly stuck with fabric. If necessary, slowly heat the print with heat gun or hair dryer and then try to scrape it with some blunt object. But be careful that fabric does not get damaged. Sometimes remover chemicals can be used, but do this with caution.