What is Glitter Printing?

Glitter printing is a modern printing technique that gives a shiny, eye-catching, and luxurious look to garments or other surfaces. It uses sparkling glitter particles available in different colors and sizes that reflect light and make any design stand out. This technique is widely used in party wear, fashion wear, kids’ clothing, promotional items, and especially on t-shirts, hoodies, jackets, and bags.

Send us your logo or design now to see how it looks with this printing technique and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Glitter Printed Products Collection.

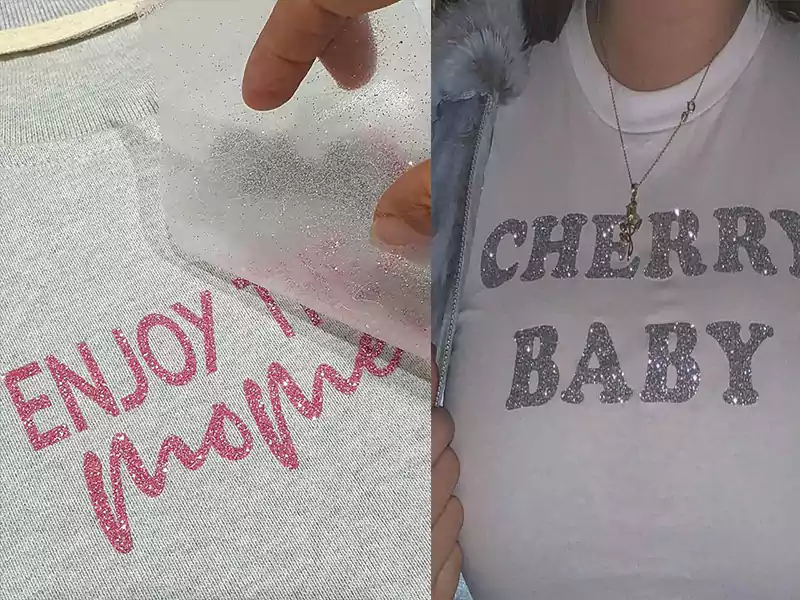

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Glitter printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Glitter printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

In this process, a special adhesive binder or heat transfer vinyl (HTV) sheet is used. Glitter powder is applied on it and then transferred onto fabric using heat press or screen printing. With heat and pressure, the glitter sticks firmly to the fabric, creating a sparkling and durable print.

The unique feature of glitter printing is its ability to instantly grab attention. It makes clothes look fashionable, special, and stylish while highlighting logos, text, or designs more prominently.

Historical Background

The idea of adding shine to clothing is not new. Ancient civilizations like Egyptians, Romans, and Indians used shiny threads, gold and silver wires, or tiny glass pieces to decorate fabrics. Although that was not “glitter printing,” the desire for sparkle led to its modern form. The regular use of glitter started in the 1930s, when American scientist Henry Roschmann invented a method to make glitter from plastic. Before that, glitter was made by grinding metals, which was expensive and fragile.

By the 1970s and 1980s, when screen printing and heat transfer techniques became popular in the fashion industry, glitter printing also emerged. At first, glitter mixed with binders was applied through screen printing, but later HTV sheets made the process easier and more precise.

Advantages of Glitter Printing

• Instantly makes any garment or design stand out.

• Gives a glamorous and fashionable appearance.

• Popular among fashion brands to highlight logos and designs.

• Offers a wide range of finishes such as gold, silver, holographic, metallic, and multi-color.

• Works on different fabrics like cotton, polyester, cotton-poly blends, spandex, and knits.

• Perfect for party wear, stage costumes, kids’ outfits, and promotional clothing.

• Attracts customers easily when displayed in retail shops.

Disadvantages of Glitter Printing

• Glitter can fade or shed after repeated washes, especially in machine wash.

• Some people with sensitive skin may face irritation or allergies if glitter comes in direct contact.

• Requires delicate care compared to regular clothes—wash inside out, in cold water, with mild detergent, and never iron directly on the print.

• Not ideal for everyday wear, as friction, sweat, or sunlight can reduce its life.

• Doesn’t stick well on all fabrics, particularly very stretchy or fuzzy ones.

How Glitter Printing is Done (Process)

1. Design Preparation – The desired design (logo, text, or artwork) is created digitally and set for cutting or screen printing.

2. Material Selection – Choose glitter type (matte, holographic, metallic) and color. Available as HTV sheets or loose powder.

3. Fabric Preparation – Fabric is cleaned and smoothed. Cotton and polyester are preferred for strong adhesion.

4. Printing Methods:

o Heat Transfer Vinyl (HTV): Design is cut on a glitter vinyl sheet, placed on fabric, and heat-pressed to stick.

o Screen Printing: Binder/glue is applied through a mesh screen, glitter powder is sprinkled, and then heat is used to set.

5. Heat Setting & Finishing – The garment is heat-pressed or dried so glitter sets permanently. Excess glitter is removed, and the print is checked.

Fabrics Suitable for Glitter Printing

• Cotton: Most popular and durable choice. Commonly used for glitter print t-shirts.

• Polyester: Works well, especially with HTV.

• Cotton-Poly blends: Flexible and suitable if the blend is balanced.

• Spandex / Lycra: Possible but tricky; requires correct binder and heat setting.

• Knitted Fabrics: Hoodies, sweatshirts, and warm clothes can be glitter-printed if the texture allows.

• Fuzzy/Textured Fabrics: Not ideal, as glitter doesn’t stick properly and peels off.

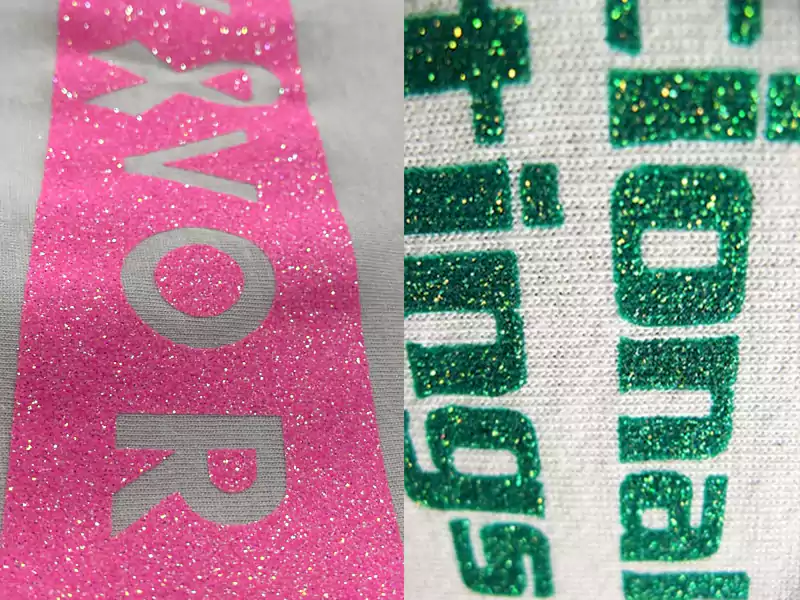

Types of Glitter Printing

• Flat Glitter Printing: Standard technique, smooth shiny finish, commonly used for t-shirts.

• 3D / Puff Glitter Printing: Glitter appears slightly raised for a bold effect.

• Heat Transfer Glitter Vinyl: Precise, neat, and long-lasting method using pre-made vinyl sheets.

• Multi-color Glitter Printing: Multiple glitter shades in one design, often used for party wear or promotional items.

• Holographic Glitter Printing: Shiny glitter that changes colors when viewed from different angles—trendy and fashionable.

Durability & Care

• Durability depends on fabric quality, printing method, and glitter material.

• High-quality HTV glitter prints can last many washes if cared for properly.

• To maintain shine:

o Wash inside out

o Use cold water and mild detergent

o Prefer gentle cycle or hand wash

o Avoid direct sunlight and hot dryers

o Never iron directly on glitter—use a cloth in between

o Store on hangers instead of folding

Common Uses of Glitter Printing

• Fashion garments: Party dresses, vintage styles, glitter t-shirts, and premium clothing.

• Promotional items: Logos and branding for events and marketing campaigns.

• Kids’ clothing: Dresses, t-shirts, sweatshirts, and accessories.

• Custom orders & gifts: Personalized t-shirts, hoodies, or bags.

• Dance & stage costumes: Eye-catching outfits that reflect stage lights.

FAQ'S

Can glitter print t-shirts be machine washed?

Yes, but only on gentle cycle, with cold water and mild detergent. Always wash inside out.

How long does glitter printing last?

With good quality material and proper care, it can last for many months or even years.

Is glitter printing hoodie suitable for daily wear?

Not recommended for everyday use—best for parties or special events.

Can glitter printing be done on any fabric?

No, works best on cotton, polyester, and blends. Not suitable for very stretchy or fuzzy fabrics.

Can glitter printing cause skin allergies?

Rarely, but low-quality glitter or direct contact may irritate sensitive skin. Always use safe, high-quality material.

Can glitter prints be removed or replaced?

No, glitter printing is permanent. Removing it may damage the fabric.