What is Discharge printing?

Discharge printing is a very interesting and high-quality technique which gives a new dimension to printed designs on fabrics. It is the process in which the original color from the fibers of a dyed fabric is removed through chemicals, and in its place, a new color or design is added. You may understand it this way that this printing does not only “finish” but creates a new and attractive effect, which is not possible with ordinary printing. Discharge printing not only adds color but first removes the already existing color.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Discharge Printed Products Collection.

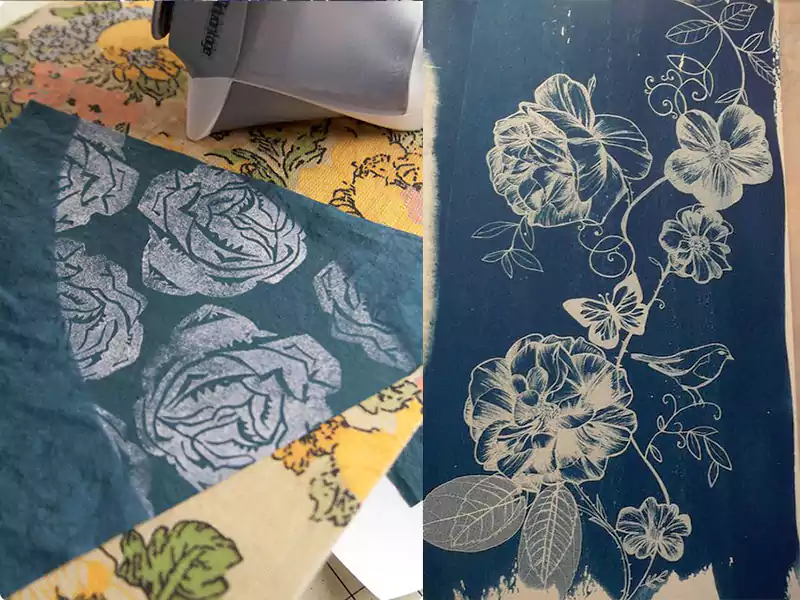

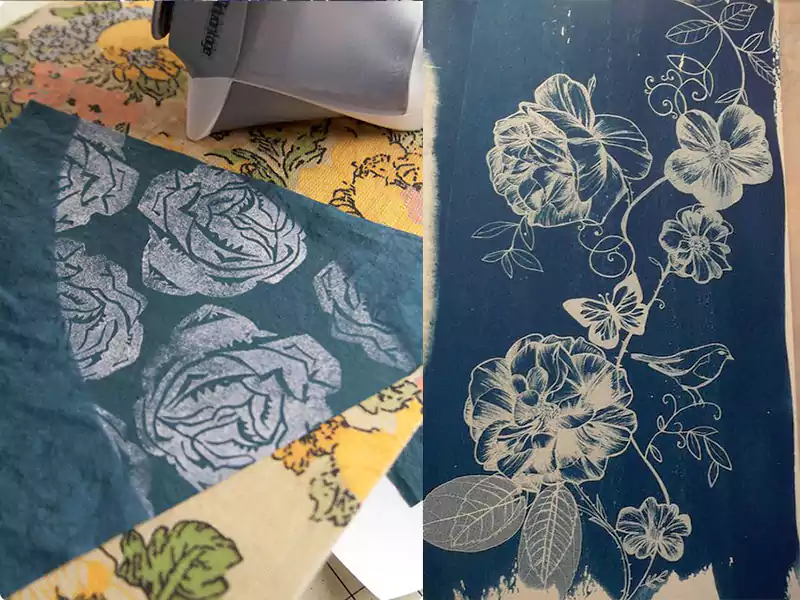

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Discharge Printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Discharge Printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

Mostly it is done on 100% pure cotton fabric, because its natural structure is most suitable for this process. Especially on dark-colored fabrics when this technique is used, its result becomes surprisingly soft, smooth, and natural-looking—such as if the color has become part of the fabric itself. This technique is especially ideal for those brands which want that their designs not only look beautiful but also give the wearer the feeling as if they are “absorbed into” the fabric. Its final result is highly durable and less damaged in washing. Discharge printing is not only a technique but an art which every time brings out a unique, beautiful, and pure creation. That is why this technique is highly popular in top-quality garment-making institutions worldwide.

Step-by-step process of Discharge Printing

Step 1: Fabric Selection. The most important thing for discharge printing is the correct selection of fabric. This printing is especially done on 100% cotton dark-colored fabrics, because these fabrics have the ability to remove (discharge) the color properly. Black, navy blue, or dark grey colors are considered more suitable for this technique.

Step 2: Pre-treatment of Fabric. The fabric is thoroughly cleaned before printing so that no dust, oil, or starch remains on it. Sometimes bio-wash or enzyme wash is also carried out so that the printing quality becomes further better.

Step 3: Preparation of Discharge Paste. For discharge printing a special paste is prepared, which mainly includes:

• Discharge agent (generally Zinc Formaldehyde Sulfoxylate)

• Printing gum or thickener

• Water and other auxiliary chemicals

If color is to be added then dischargeable pigment or reactive dyes are added.

Step 4: Screen Printing Application. This paste is printed in the form of a design on the fabric through a screen-printing machine. This work is exactly the same as normal screen printing, the only difference is of the paste.

Step 5: Drying the Printed Fabric. The printed fabric is put into dryers and dried at 80–100°C for some time so that the paste fully sets and in the next stage reacts properly.

Step 6: Curing or Steaming. Now comes the most important stage—heat setting or curing. It is cured at 160–180°C so that with the help of the discharge agent present in the paste, the original color of the fabric is removed and at the same time, the new color (if added) gets absorbed. This is the process which creates the discharge effect.

Step 7: Final Washing & Finishing. When the fabric is fully cured, then it is washed so that the remaining chemicals or paste are cleaned. Then it is processed with softening, fragrance, and compacting so that the finishing of the fabric becomes the best.

Step 8: Quality Check & Packing. In the end, all printed units are inspected so that no defect remains. Then they are folded and packed according to the brand.

Care Guide for Protection of Discharge Printing

Washing precautions:

• Always wash with cold water: washing with hot water can fade the print.

• Use mild and neutral detergent: avoid bleach or strong chemical detergents because they can remove color.

• Wash inside out: washing clothes turned inside out protects the design from direct rubbing.

• Prefer hand wash instead of machine wash: the harsh movement of the machine can damage the print quickly.

• Wash separately in the first 2–3 washes: so that color does not transfer from the fabric to other clothes.

Drying precautions:

• Avoid direct sunlight: because UV rays can fade the print.

• Avoid direct heater or high-heat dryer: heat can spoil the discharge print.

• Dry in shade in natural air: drying in natural air in shade keeps the print preserved for longer.

Ironing precautions:

• Do not iron directly on the print: if necessary, place a light cloth and then iron or iron inside out.

• Do not use very high temperature iron: use medium or low temperature so that the print does not get damaged.

General instructions:

• Do not spray perfume or deodorant directly on the print: chemicals can damage the print.

• Avoid bad environments like damp or very hot rooms: both fabric quality and print can be affected.

• Avoid excessive rubbing or heavy physical work while wearing: like gym or workout, so that the print does not get damaged quickly.

FAQ'S

What is discharge printing?

Discharge printing is a special printing technique in which the fabric’s color is removed through a chemical process and in that place a new color or design is printed. This method is especially used on dark-colored fabrics, like black or navy blue.

Can colorful prints also be done through discharge printing?

Yes, it is also called discharge with pigment, in which color is removed and with new colors beautiful designs are made.

Can discharge printing only be done on 100% cotton?

Yes, discharge printing gives the best results only on 100% pure cotton fabrics. On synthetic or blended fabrics, removing the color completely and clearly through this chemical process is not possible.

What are the benefits of discharge printing on a T-shirt?

• Soft and breathable print

• Print merges with the fabric (low hand-feel)

• Does not feel very metallic or rubber-like

• Best for vintage-style designs

How is discharge printing done on a hoodie?

The process of discharge printing on a hoodie is the same as on a normal T-shirt, but since the structure of a hoodie is thicker, therefore pressure, temperature, and time are specially taken care of so that the print becomes deep and permanent.

If discharge printing on a hoodie or T-shirt gets damaged, how can it be removed?

Discharge printing cannot be completely removed because it changes the original color of the fabric. However, a new print can be done on top of it to cover it or it can be used to give a creative distressed look.

What precautions should be taken for washing clothes with discharge printing?

• Always wash with cold water

• Use mild detergent for washing

• Do not wash with completely new clothes

• Avoid machine dryer, only dry in air

Is discharge printing eco-friendly?

Modern discharge inks and compounds are mostly made eco-friendly, but some older formulas can be harmful for the environment. That is why it is better to use eco-friendly discharge ink.

Does discharge printing disappear after washing?

If it has been done correctly and the care instructions of the garment are followed, then discharge printing remains for many years. However, with low-quality chemicals or improper washing it can fade.