What is DTG printing?

Printing, which is called Direct to Garment Printing, is a modern digital technology through which printing is done directly on fabric. DTG is just like printing on paper with an inkjet printer. In this technique, special DTG printers are used which, by using water-based ink, transfer complex, colorful, and high-resolution designs directly on cotton or other absorbent fabrics. DTG printing is considered best especially for small quantities or print-on-demand, because in this there is no need for any screen or preparation. That is why it is becoming a faster, cheaper, and environmentally better alternative. With DTG printing not only photo-realistic designs, gradient effects, and fine details can be easily transferred, but brands and printing houses also get flexibility that they can prepare every order in a unique way without any pressure.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

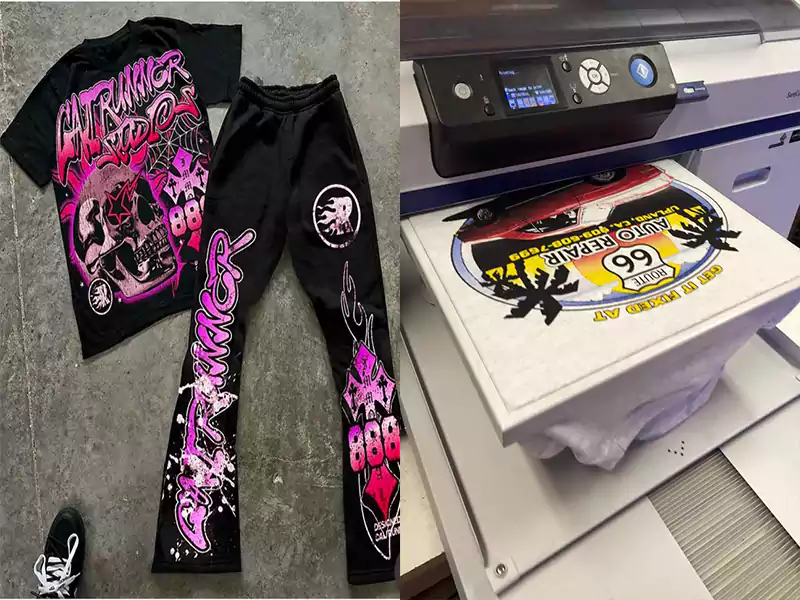

From Concept to Perfection Explore Our DTG Printed Products Collection.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in DTG printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how DTG printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

History of DTG Printing

The story of DTG printing is not merely of a printing technique, but a tale of revolution in the textile industry. It was that moment when creativity was directly transferred onto clothes — “Changed the canvas, but the passion remained the same.” This modern technology started in 1996, when the first DTG printer was introduced. This printer was made in America and for the first time showed the world that ink can write poetry not only on paper, but also on fabric. But as every revolution takes time, DTG also took about a decade to gain popularity. After 2005, as the printing industry started moving in a digital direction, in the same way DTG began to challenge traditional screen printing. The greatest strength of DTG was that you could print a complex and colorful design on a single shirt without any expensive screen or setup. This was like the fulfillment of a dream for brands, designers, and startups. Today, DTG printing has become the first choice of thousands of garment manufacturers worldwide, especially for those who want quality, color detail, and fast production.

Step-by-step Journey of DTG Printing

DTG printing is an art which is a beautiful combination of digital skill, textile knowledge, and printing science. In every stage, elegance and modern technology can be seen, from which on garments emerges a design that not only pleases the eyes but enters the heart.

1. Magic of Design (Design Creation)

The first step of DTG printing is a high-quality digital design, which is often prepared in modern software like Adobe Illustrator or Photoshop. This design is fine-tuned in CMYK format so that during printing, every color appears on fabric with full intensity.

2. Garment Selection

This stage is as important as the design itself. For best results, 100% cotton or combed cotton is preferred, because it absorbs printing more and shows colors beautifully.

3. Pre-Treatment Magic

This is the hidden magic behind every successful DTG print. Especially before printing on dark-colored fabrics, a pre-treatment liquid spray is applied which not only makes the print bright but also helps colors to stick to the fabric.

4. Heat Pressing

After pre-treatment, the fabric is kept under a heat press machine for a little while so that the surface becomes smooth and ready for the printer. This step is done to absorb the liquid into the fabric and remove moisture.

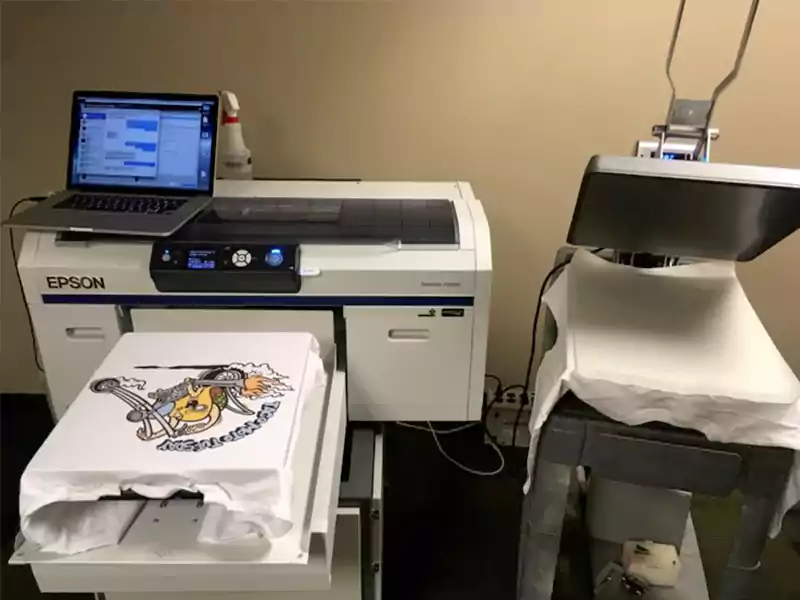

5. DTG Printing Itself

Now comes the real printing! The DTG printer works exactly like an inkjet printer, but for fabrics. The printer prints the design directly on the fabric, in which every line, every shade, and every color emerges with full glory.

6. Final Heat Setting

When printing is completed, to make this print permanent it is again kept under a heat press. This process is called curing. This makes the print washable, durable, and colorfast.

7. Final QC & Touch Up (Quality Check)

In the end, every garment is carefully checked so that no smudge, line break, or color bleeding exists. If everything is perfect, then the garment is sent for packing.

A Small Idea, Long-lasting Guarantee: Care and Instructions for DTG Printing

These few simple rules can preserve the beauty of your printed T-shirts or other garments for years:

1. First Wash — do it gently:

When washing a newly printed garment for the first time, always turn it inside out and wash in cold water. This keeps the colors safe and the shine of print does not fade.

2. Avoid hot water:

Never wash DTG printed clothes in hot water. Hot water can affect the print coating which can damage the design.

3. Hand or Machine? – Use machine on gentle mode:

Select “gentle cycle” or “delicate mode.” Strong washing cycles can damage the print.

4. Use of bleach forbidden:

Do not use any kind of bleach or harsh chemical. These remove the colors and also damage fabric fibers.

5. Limited use of dryer:

If possible, dry in air. If dryer must be used, do it on low temperature. Too much heat can tear or burn the print.

6. Method of ironing:

Never iron directly on printed area. If ironing is needed, turn the fabric inside out or put a cloth on top and do it on low heat.

7. Don’t forget to turn inside out before washing:

Turning the garment inside out every time before washing is a small but very effective act that increases the life of print.

8. Avoid dry clean:

Do not dry clean DTG printed clothes because the solvents used in it can damage the print.

FAQ'S

What is DTG Printing?

DTG printing means Direct-to-Garment, a modern printing technique in which printing is done directly on fabric through printer, just like it is done on paper. It is especially suitable for 100% cotton or cotton-mix fabrics.

What is difference between DTG and Screen Printing?

• DTG Printing: Best for small quantities, complex designs, color details

• Screen Printing: Suitable for bulk quantities, simple designs, lower cost

Is DTG printing suitable for fashion or branding?

Absolutely, because it has the ability to provide high-resolution, full-color print, which is ideal for fashion brands and custom designs.

Is DTG printing good quality?

Yes, DTG (Direct to Garment) printing is considered high-quality printing, especially when it is done correctly and with good quality machine, ink, and fabric. In DTG printing, ink directly absorbs into fibers of fabric, as a result the print looks very smooth, soft, and detailed. It is especially best for photo designs, gradients, and color complexity. However, if low-quality fabric or ink is used, quality can be affected. With proper wash care these prints last for a long time.

On which fabrics can DTG printing be done?

DTG printing is generally done on fabrics that are 100% cotton or at least 50% cotton. For this printing, smooth, low-knit fabrics are considered best.

How long does DTG printing last?

If proper care is taken, DTG printing can maintain its quality for 30–50 wash cycles.

Is it better to wash DTG printed garments by hand?

Yes, if possible, washing by hand in cold water is best for DTG print.

Is screen printing better than DTG?

Both printing techniques are best in their own places, but difference is according to use:

• Screen Printing: For bulk quantity orders, more effective and cheaper. It is more durable and best for simple or limited color designs.

• DTG Printing: Better for small quantity orders, complex and colorful designs, or urgent orders. In this, less preparation is needed and very detailed work can be done. So, if you want to print large quantity simple designs, then screen printing is better, but if you need less quantity and more detail, then DTG printing is better.

Does DTG printing get ruined by washing?

If care is not taken properly, DTG print quality can be affected. But if washing is done according to instructions (e.g., turning inside out, washing in cold water, without bleach), then the print lasts for many washes.

Is DTG printing waterproof?

No, DTG printing is not waterproof, but it is water-resistant if it has been properly fixed.

Is DTG printing instantly prepared?

Yes, for small quantity orders this is a fast and effective printing technique, which is usually completed within 1–2 days.

How to remove DTG print?

Completely removing DTG print from fabric is difficult because ink gets absorbed inside fabric. However, some methods can be tried, although complete cleaning is not guaranteed:

1. High heat press or iron: At high temperature, print can be broken by heat, due to which ink starts to crack.

2. Chemical removers: Some specific chemicals (like “ink removers” or bleach-based solutions) can be tried, but they can damage fabric.

3. Sandpaper or abrasive sponge: By rubbing softly, print can be blurred, but it can damage fabric surface.

4. Washing repetition: Repeated washing can fade the print, especially if hot water and strong detergent are used.

But keep in mind that completely removing DTG print is often not possible without damaging fabric.

What precautions are necessary to preserve DTG print?

• Always wash inside out

• Wash in cold water

• Dry in air instead of machine dryer

• Avoid bleach and harsh chemicals

• Don’t iron directly on print

Is DTG printing possible on every color fabric?

Yes, but on dark fabrics (like black or navy), before printing, a white under-base has to be applied so that colors appear clearly.

How much does DTG printing cost?

Answer: It depends on design size, colors, and quantity of order. Generally, in small orders, the price is slightly higher.

Can DTG printing be done on hoodie?

Yes, DTG printing can be done on hoodie, but some points must be kept in mind:

• Fabric: Hoodies of 100% cotton or cotton-rich blend are more suitable for DTG printing because ink absorbs well in them.

• Color: On light-colored hoodies (like white, light gray) the print comes out clearer, while on dark hoodies a white under-base must be applied before printing.

• Thickness: Hoodie fabric is usually thick, so printer’s height settings need to be adjusted so that nozzle keeps proper distance from fabric.

• Design position: Since hoodie may have zip, pocket, or cords, therefore print position is selected carefully so that print does not get spoiled.

If all these factors are correct, then DTG printing can be done very beautifully on hoodie as well.

How to remove DTG print from T-shirt?

DTG print removal is somewhat difficult because it has been absorbed into fabric. Normal home methods are not effective. However, through professional chemicals or fabric bleaching it can be removed to some extent, but fabric can also be damaged.

Is DTG printing eco-friendly?

Yes, it is an eco-friendly printing method because it uses less water and ink is also water-based.

Can we reprint on DTG printed fabric?

No, reprinting on already printed garment with DTG is difficult, because the first print ink makes the surface uneven.