What is Silicone 3d printing?

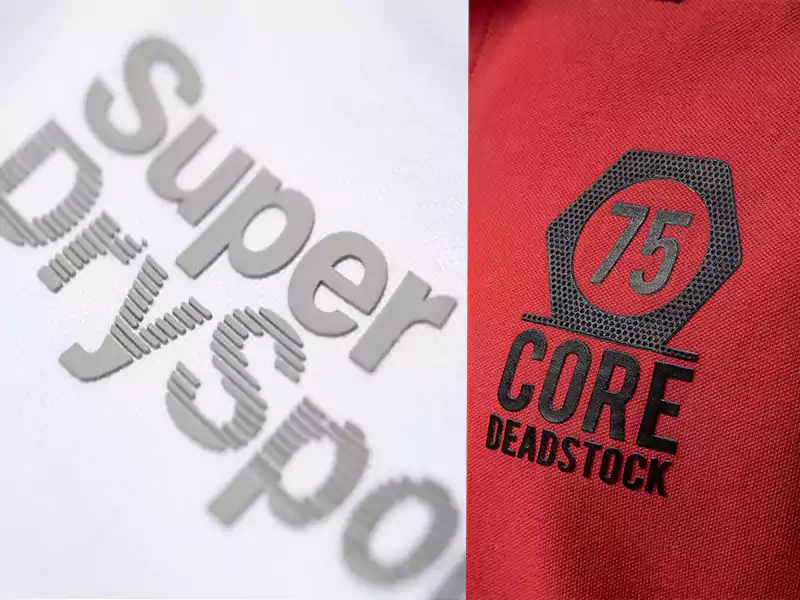

If there is any best example of embossed, soft yet durable printing on fabrics, it is 3D silicone printing. This modern and attractive printing technique is especially for those brands that not only want to make their products unique but also give the wearer a different feel. In silicone printing, a special type of liquid silicone is applied on the surface of the fabric in a 3D style, which not only looks attractive but also gives a different texture and flexible feeling to the touch.

Send us your logo or design now to see how it looks with this printing technique — and get a free 3D mockup within 24 hours.

From Concept to Perfection Explore Our Silicone 3d Printed Products Collection.

As an experienced and professional clothing manufacturer, we specialize in bringing innovation and quality together. With our expertise in Silicone-3d- printing technique, we have crafted a wide range of products including t-shirts, hoodies, sweatshirts, and tracksuits that stand out with their unique appeal. This carousel showcases how Silicone-3d-printing adds depth, texture, and vibrant detail to garments, turning simple apparel into premium fashion pieces. Backed by years of manufacturing experience and advanced printing skills, we help brands create collections that not only look stunning but also reflect durability and craftsmanship. Trust our expertise to transform your vision into reality with precision and style.

The special thing about it is that compared to other printing techniques it is more long-lasting, waterproof, and heat-resistant, which makes it best for streetwear, activewear, and high-fashion garments. The biggest advantage of silicone printing is that it highlights the designs in an embossed form, whether it is a logo, text, or complex graphics. That is why today’s modern fashion brands, sports companies, and streetwear labels are rapidly adopting this technology. The material used in this printing is eco-friendly and safe for skin, which makes it a modern, sustainable, and user-friendly choice.

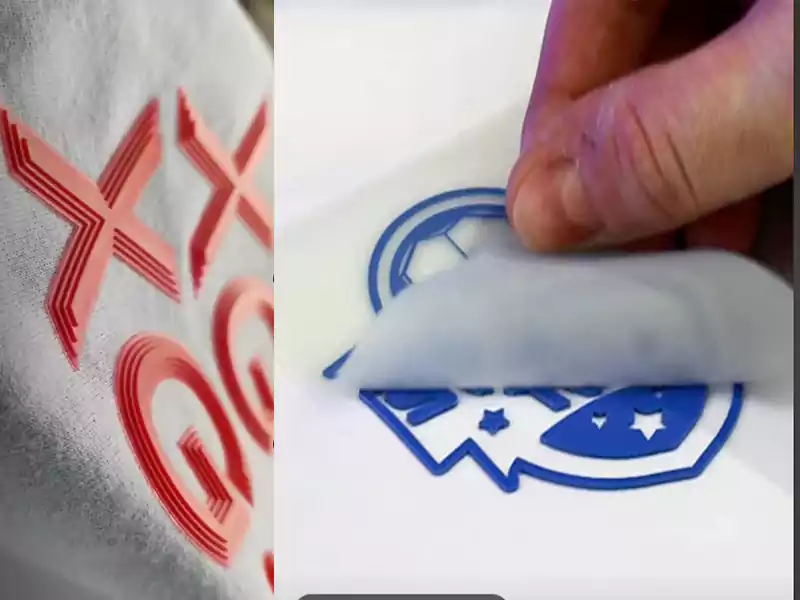

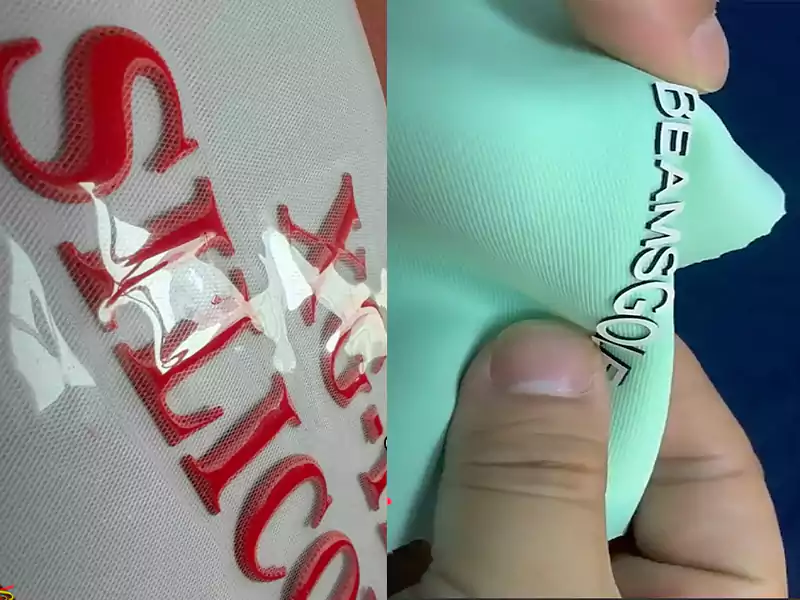

Two Basic Methods of Silicone 3d Printing

Screen printing method is better for flat and continuous designs such as large area prints, while heat transfer molded silicone is especially used for logos, patches, or specially embossed designs. Both methods are used for high-quality silicone prints, but their machinery, technique, and cost are different.

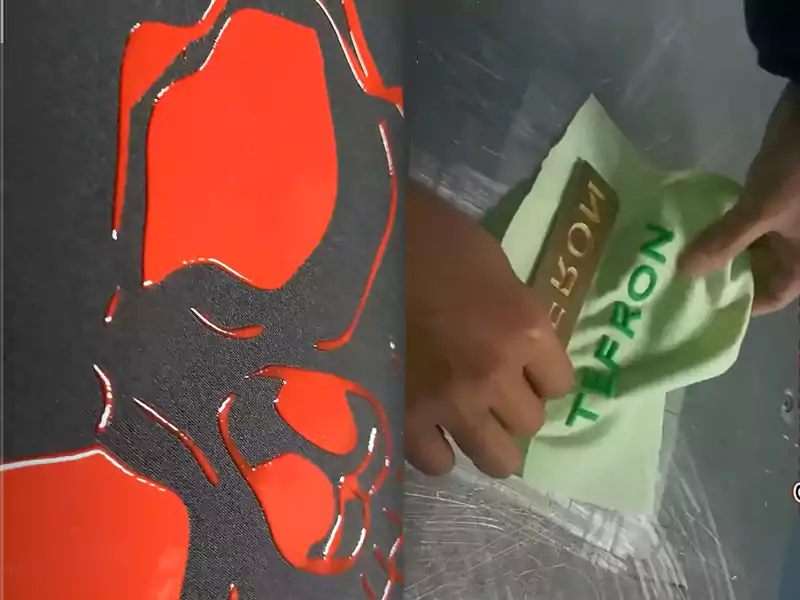

1. Conventional Screen-Based Silicone Printing (Silicone Screen Printing)

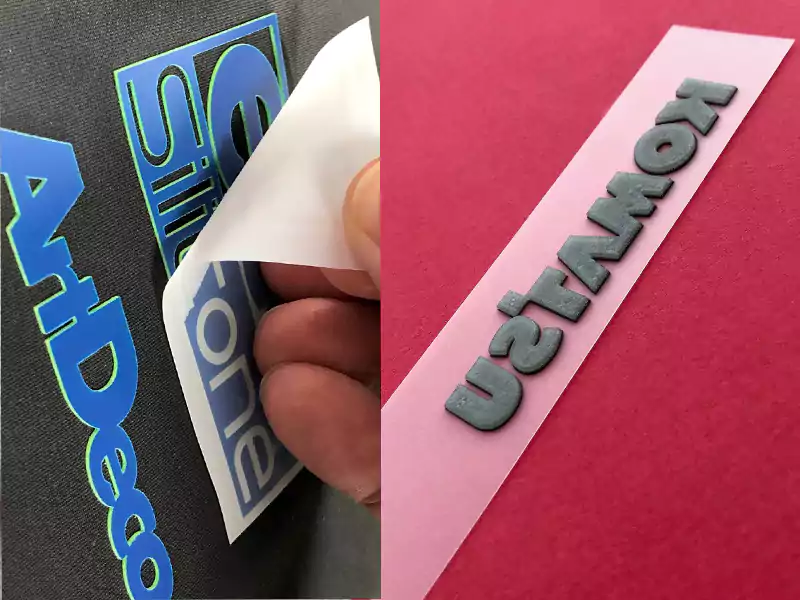

2. Silicone Heat Transfer / Molded Silicone Printing

Method No. 1: Silicone 3d Printing Through Screen

This is the method done with a screen printing machine. Generally, it is used on sportswear, swimwear, and stretchable fabrics because silicone print is flexible, glossy, and durable.

Step 1: Preparation of Design

• Design is prepared on computer (in CorelDraw or Illustrator)

• Separate films are made for each color

Step 2: Making of Screen

• Emulsion is applied on mesh (screen mesh) and dried

• Then film is placed and exposed to light in exposure unit so that design is engraved

Step 3: Preparation of Silicone Ink

• Silicone ink is prepared in two parts:

○ Part A (Base)

○ Part B (Catalyst)

• Both are mixed in a specific ratio (e.g., 10:1)

• Pigment is added for coloring

Step 4: Printing Process

• Screen is placed on fabric

• Silicone ink is poured on screen and pressed through squeegee

• Each color is printed separately with a separate screen

Step 5: Flash Curing

• After each layer, fabric is dried in flash cure machine (80–120°C)

Step 6: Final Curing

• After complete print, at 150°C for 2–3 minutes in heat press or oven so that ink is fully cured

Method No. 2: Molded or Heat Transfer Silicone 3d Printing

This is the method in which the design is already engraved in a die or mold, then applied on fabric. It is also called Molded Silicone Heat Transfer or Patch Silicone Printing.

Step 1: Preparation of Mold or Die

• A mold is prepared through CNC machine or chemical etching

• The required design is engraved in the mold

Step 2: Preparation of Silicone Mix

• Base silicone + Catalyst are mixed

• Pigment (color) is added

Step 3: Filling Silicone in Mold

• Prepared silicone mixture is filled in the mold

• Especially with micro-vacuum or heating plate this work is done so that bubbles do not remain

Step 4: Curing of Silicone

• Mold is placed at 120–150°C in oven or heat plate for few minutes

• This makes silicone hard and flexible

Step 5: Applying Prepared Patch or Label on Fabric

• Now this flexible patch or label is placed on fabric

• By heat press machine at about 150°C for 10–15 seconds it is pressed

Step 6: Cooling and Checking

• Fabric is cooled and checked whether silicone is properly stuck or not

• If needed, it can be pressed again

Care Instructions for custom Silicone Printed Garments

1. Before Washing Instructions:

• Always turn the garment inside out before washing so that print remains safe from direct friction or rubbing.

• Protect from harsh stains or chemicals before washing, because some stain removers can damage silicone coating.

2. Machine Wash or Hand Wash?

• Hand wash is better. But if machine wash is necessary:

o Select Gentle cycle or Delicate Mode

o Use cold water, hot water can soften the print or reduce adhesion strength.

3. Use of Soap or Detergent:

• Use mild or non-abrasive detergent.

• Do not use bleach, fabric softener, or stain remover because these chemicals can damage silicone integrity.

4. Drying Rules:

• Avoid direct sunlight. Strong sunlight can fade or weaken silicone print.

• Air dry — means dry in shade in open air.

• Avoid tumble dryer (machine drying), especially high heat cycle.

5. Ironing:

• Do not iron directly on silicone print.

• If ironing is necessary, turn garment inside out and iron at low temperature or place a cotton cloth on silicone print and then iron.

6. Storage Method:

• While folding garment, protect silicone print from sticking or rubbing with other clothes.

• Hanging method is better instead of folding, so that no crease or breakage comes in print. What Not To Do (Avoid):

• Bleach, hot dryer, hard brush, and chemical cleaning.

• Avoid frequent bending, stretching, or scratching of silicone print.

FAQ'S

What is Silicone Printing?

Silicone printing is a special type of 3D rubber-like printing technique in which embossed print is created on fabric through silicone ink, which not only looks beautiful but is also very durable.

On what types of fabrics can silicone 3d printing be done?

This printing can be done on almost every type of fabric like cotton, polyester, lycra, jersey fabric, sportswear, and activewear.

Can clothes be ironed after silicone 3d printing?

Yes, but caution is necessary. Iron printed area inside out or by using ironing paper at low heat.

Is it safe to wash silicone printed garment in machine wash?

Yes, if washed according to care instructions, like in 30–40°C water, using mild detergent, then machine wash is safe.

In what types is silicone printing done?

Silicone printing is done by two main methods:

1. Through conventional screen printing

2. Through die-cast or molding method where design is pre-engraved in die

Does silicone 3d printing leave color or crack?

If standard silicone ink is used, it does not leave color, does not crack, and does not break.

How much does custom silicone printing cost?

Its cost depends on many factors such as complexity of design, size, type of fabric, and order quantity.

Does silicone printing peel off from fabric?

If silicone printing is of high quality and done at correct temperature and pressure, it is very durable and stays on fabric for many years.

Is silicone printing eco-friendly?

Yes, most modern silicone inks are eco-friendly and non-toxic, but it depends on the quality of ink.

Is silicone printing waterproof?

Yes, silicone ink has waterproof properties, so it is not affected by rain or sweat.

Does silicone printing get damaged by washing?

No, if garment is washed correctly (like in mild warm water, turning inside out), then silicone print does not get damaged.

What is the difference between silicone printing and rubber printing?

Silicone printing is more flexible, softer, and longer lasting than rubber printing. Silicone finish is also glossier and cleaner.

After silicone printing how long should garment not be used?

Generally, after printing the garment fully cures in 24 hours. During this time it should not be washed or bent hard.

What is the complete process of applying silicone printing on fabric?

First, design is prepared, then silicone ink is applied, and through special machines with heat and pressure it is adhered on fabric. (More detail is given above in the page).

Is silicone printing better for sports or gym wear?

Yes, silicone printing is especially suitable for sportswear, gym wear, and activewear because it withstands sweat, stretching, and washing.

Why is brand logo or label printed with silicone printing?

Because it gives a premium and professional finish, and makes branding clear and durable.